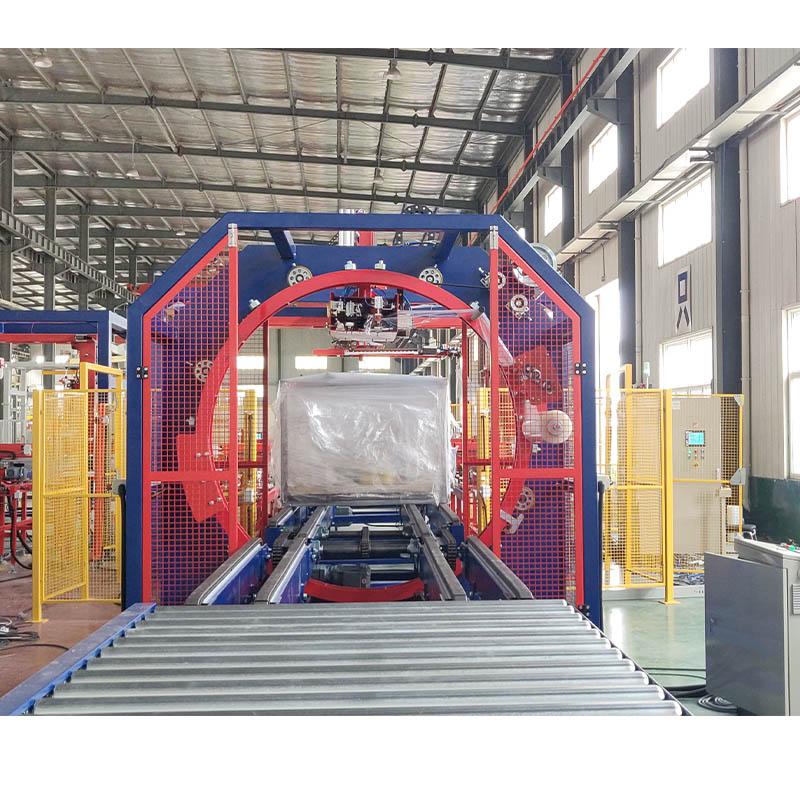

Horizontal Packaging Machine Conveying System

Horizontal wrapper wraps merchandise that won`t suit on a turntable, require banding, compression or more packing for shipment. It has a confirmed file of success in many industries such as profiled product, tubular product and plank stuff etc.

We affords a huge range of picks to meet your precise requirements. Each purposes is evaluated to grant the proper answer to your needs.

Control System

PLC electric powered control

Ring rotating pace managed via the inverter

Inbound & outbound conveyor velocity managed with the aid of the inverter

Start and end cycles are managed by way of photocells

Auto movie cuting and snatch unit

Top 6 aspects strain avaible for mild objects

Technical data

Item | Specification |

Wrapping specifications | (500-1300)mm*(500-1200)mm. |

Packing height | 2400mm |

Packaging efficiency | 30-60 loads/H available. (Option: or 20-40 loads/H) |

Arm speed | 0-35rpm frequency control. (Option 15rpm, 25rpm) |

Arm performance | High sensitivity emergency brake system, the arm automatically reset. |

Film carriage system | Pre-stretch film carriage, stretch ratio up to 300%, automatic film feeding & cutting device, adjustable speed. |

Lifting column | Chain structure, speed variable frequency adjustable. |

Control system | PLC programmable control, wrapping layer adjustable, automatic height sense. |

Machine weight | 680KG (without support) |

Machine dimensions | 3440mm*1800mm*3220mm (without convey line) |

Power/ voltage | Arm 1.1/1.5kw, Film carriage 0.37kw, lift 0.37kw/0.55kw, conveyor 0.75kw/AC220V |

Option: Safety warning and protection fence, Photo-eye protection for infeed and outfeed goods (Conveyor line) | |

-PLC control

--Reinforce wrap permit greater wrap on identical location

--Film Tension Control adjustment on the panel

--0-35RPM arm variable pace via frequency changer

--Separate variable carriage up/down velocity

--Cycle pause capability

--Separate start, reset and emergency end buttons

--Manual carriage up/down swap

--Turntable jog button

--Flash mild for desktop in operation

--Rotary arm end by using security bumper and reflection photoeye sensing and impediment in the rotating vicinity

The electronic control system is the core of the equipment execution layer in the logistics system. It is connected upward to the dispatching computer of the logistics system to receive material delivery instructions; it is connected downward to various execution equipment to realize the driving of the underlying equipment and the detection and identification of the conveyed materials; to complete the material conveyance Process control and information transmission. In addition, it also provides rich and vivid man-machine interface, safety protection measures and multiple operation modes to assist staff in equipment operation and maintenance, which is an important part of the automated logistics system.