Technical dataItemSpecificationWrapping specifications(500-1300)mm*(500-1200)mm.Packing height2400mmPackaging efficiency30-60 loads/H available.

Contact Now

Technical specification MWS Robot PRS MachineDrive speed robot: 1-4 m/min.Max. speed wrapper :90 m/minTotal weight:approx.

Contact Now

Technical dataItemSpecificationWrapping size500-1200mm (L) *500-1200mm (W)Packaging heightMax.2400mm (1800/2800mm available)Work efficiency20-40 loads/HTurntable speed0-15RPM (adjustable, soft start & stop)BearingMax. 1500kgsTurntable sizeD=1650mm, H=78mmFilm carriageDriven pre-stretch carriage, move up and down on side of the towerStretch ratioUp to 150%TowerDouble chain design.

Contact Now

Control systemPLC control systemPhoto eye pallet height sensor3-12 RPM variable turntable speed by frequency changerFilm carriagePowered pre-stretch system to 300% to min film consumptionFilm delivery barlable speed by spparate AC Drive MotorHeavy duty double-chain carriage lift, calm and safetyTechnology DataMax load size(mm): 1200(L)X1200(W)X2400(H)Turntable dia: 1650mmTurntable Height: 77mmTurntable weight capacity: 2000kgsTurntable speed: 3-12rpmElectrics: 220V 50HZ 1 phasePower: 1.5KWOptionRampTop plateTurntableGo home position after wrap cycle finishedSoft start/soft stopHeavy duty

Contact Now

ItemSpecificationWrapping specifications(500-1300)mm*(500-1200)mm.Packing height2400mmPackaging efficiency30-60 loads/H available.

Contact Now

Wrapping size: L(500-1300)mm*W(500-1200)mmWrapping height:H(1800-2600)mmWrapping speed:30-60pallets/hRotating speed of the rotary arm:0-35rpm, variable frequency control motor drivingFunction of rotary arm:automatic brake system, automatic resetFilm carriage:pre-stretch film carriagethe stretch ratio up to 250%automatic stretch film feedingFilm lifting guide rail: double chain structure, the lifting speed adjustableControl system: PLC control system, wrapping layers and times adjustableAutomatic height detection of the goodsAuto film feeding: &

Contact Now

ItemSpecificationWrapping specifications(500-1300)mm*(500-1200)mm.Packing height2400mmPackaging efficiency30-60 loads/H available.

Contact Now

SpecificationsModelUCR-T2000APacking Size Max.W 1200 mm × L 1200 mmWrapping Height Max.2000 mmTurntable Diameter2000 mmLoad Capacity2000 kgEfficiency40 - 60 loads/hFilm Delivery SystemPowered Roller Pre-Stretch System Up to 250 - 300%Turntable Height470 mmTurntable Rotation Speed0 - 12 rpm, variableRoller Table Width (BF)1300 mmConveyor Speed8 m/min, ConstantAutomatic Film Clamper and CutterStd.Stretch FilmLLDPE Stretch Film in 500 mm width × 15 - 35 um thickness; Film Reel in 76 mm core diameter × Max.

Contact Now

Control systemPLC control systemPhoto eye pallet height sensor3-12 RPM variable turntable speed by frequency changerTurntableGo home position after wrap cycle finishedSoft start/soft stopHeavy duty chain driveFilm carriagePowered pre-stretch system to 300% to min film consumptionFilm delivery barlable speed by spparate AC Drive MotorHeavy duty double-chain carriage lift, calm and safetyTechnology DataMax load size(mm): 1200(L)X1200(W)X2400(H)Turntable dia: 1650mmTurntable Height: 77mmTurntable weight capacity: 2000kgsTurntable speed: 3-12rpmElectrics: 220V 50HZ 1 phasePower: 1.5KWPacking

Contact Now

Control systemPLC control systemPhoto eye pallet height sensor3-12 RPM variable turntable speed by frequency changerTurntableGo home position after wrap cycle finishedSoft start/soft stopHeavy duty chain driveFilm carriagePowered pre-stretch system to 300% to min film consumptionFilm delivery barlable speed by spparate AC Drive MotorHeavy duty double-chain carriage lift, calm and safetyTechnology DataMax load size(mm): 1200(L)X1200(W)X2400(H)Turntable dia: 1650mmTurntable Height: 77mmTurntable weight capacity: 2000kgsTurntable speed: 3-12rpmElectrics: 220V 50HZ 1 phasePower: 1.5KWPacking

Contact Now

Wrapping size: L(500-1300)mm*W(500-1200)mmWrapping height:H(1800-2600)mmWrapping speed:30-60pallets/hRotating speed of the rotary arm:0-35rpm, variable frequency control motor drivingFunction of rotary arm:automatic brake system, automatic resetFilm carriage:pre-stretch film carriagethe stretch ratio up to 250%automatic stretch film feedingFilm lifting guide rail: double chain structure, the lifting speed adjustableControl system: PLC control system, wrapping layers and times adjustableAutomatic height detection of the goodsAuto film feeding: &

Contact Now

Control systemPLC control systemPhoto eye pallet height sensor3-12 RPM variable turntable speed by frequency changerTurntableGo home position after wrap cycle finishedSoft start/soft stopHeavy duty chain driveFilm carriagePowered pre-stretch system to 300% to min film consumptionFilm delivery barlable speed by spparate AC Drive MotorHeavy duty double-chain carriage lift, calm and safetyTechnology DataMax load size(mm): 1200(L)X1200(W)X2400(H)Turntable dia: 1650mmTurntable Height: 77mmTurntable weight capacity: 2000kgsTurntable speed: 3-12rpmElectrics: 220V 50HZ 1 phasePower: 1.5KWPacking

Contact Now

Wrapping dimensionWidth: 600-1250mmDepth: 50-150mmLength: 1800-2600mmWeight:20-120 kgsRotating ring speedMax.

Contact Now

ItemSpecificationWrapping specifications(500-1300)mm*(500-1200)mm.Packing height2400mmPackaging efficiency30-60 loads/H available.

Contact Now

ItemSpecificationWrapping specifications(500-1300)mm*(500-1200)mm.Packing height2400mmPackaging efficiency30-60 loads/H available.

Contact Now

Packing Size Max.W 500 - 1200 mm × L 500 - 1200 mmTurntable Diameter1650 mmWrapping Height Max.2500 mmLoad Capacity2000 kgEfficiency20 - 40 loads/hTurntable Height85 mmTurntable Speed0 - 12 rpm, variablePre-StretchPowered Roller Pre-Stretch System Up to 250 - 300%Stretch FilmLLDPE Stretch Film in 500 mm width × 15 - 35 um thickness; Film Reel in 76 mm core diameter × Max.

Contact Now

Wrapping size: L(500-1300)mm*W(500-1200)mmWrapping height:H(1800-2600)mmWrapping speed:30-60pallets/hRotating speed of the rotary arm:0-35rpm, variable frequency control motor drivingFunction of rotary arm:automatic brake system, automatic resetFilm carriage:pre-stretch film carriagethe stretch ratio up to 250%automatic stretch film feedingFilm lifting guide rail: double chain structure, the lifting speed adjustableControl system: PLC control system, wrapping layers and times adjustableAutomatic height detection of the goodsAuto film feeding: &

Contact Now

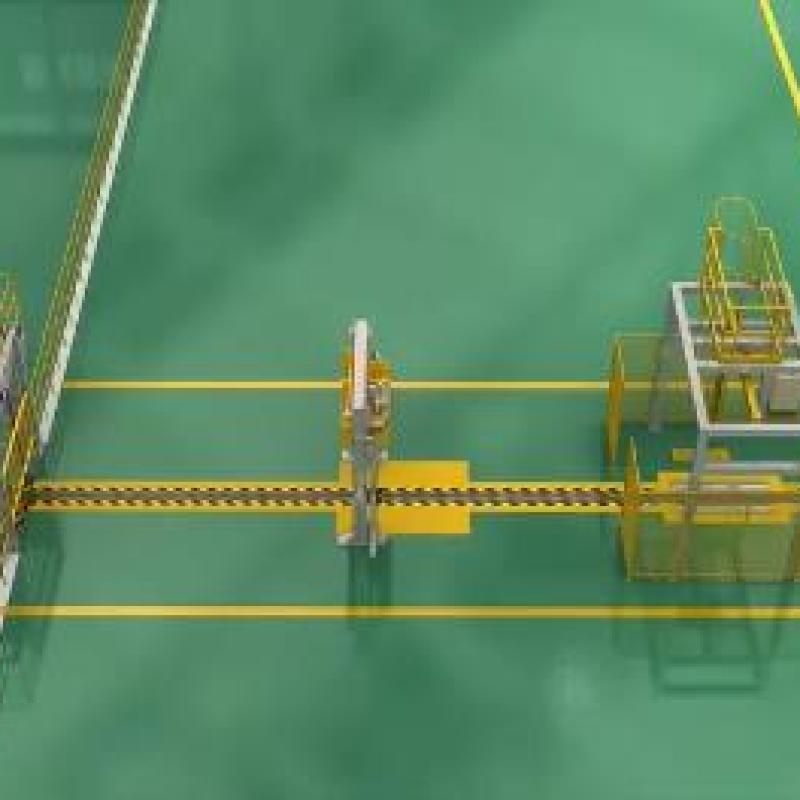

PP strap width9, 12, 15, 19mm, thickness 0.8mmPP strap splicing:electrical hot melt splicing,Splicing position580mm high above the conveyor. The pallet should not be less than 700mm in heightStrapper methodthe main machine move stroke is 400mm, mechanical sword strappingPlug between main control cabinet and wrapper for easier installation and maintenance.

Contact Now

ItemSpecificationWrapping specifications(500-1300)mm*(500-1200)mm.Packing height2400mmPackaging efficiency30-60 loads/H available.

Contact Now

ItemSpecificationMax. load size (LxWxH)(500-1300)mm×(500-1200)mm×(1800-2400)mm.Packing efficiency20-40 loads / hourRotary arm speed0-15 rpm Frequency controlPower supplyAC 220VMax load capacityFloor capacityWorking ambienceIndoor, normal temperatureMachine dimensionsSubject to final designSlewing bearing drive system;Soft start/soft stopWhen wrapping process finished as set, the arm auto back to home position.

Contact Now

Control systemPLC control systemPhoto eye pallet height sensor3-12 RPM variable turntable speed by frequency changerTurntableGo home position after wrap cycle finishedSoft start/soft stopHeavy duty chain driveFilm carriagePowered pre-stretch system to 300% to min film consumptionFilm delivery barlable speed by spparate AC Drive MotorHeavy duty double-chain carriage lift, calm and safetyTechnology DataMax load size(mm): 1200(L)X1200(W)X2400(H)Turntable dia: 1650mmTurntable Height: 77mmTurntable weight capacity: 2000kgsTurntable speed: 3-12rpmElectrics: 220V 50HZ 1 phasePower: 1.5KWPacking

Contact Now

ItemSpecificationWrapping specifications(500-1300)mm*(500-1200)mm.Packing height2400mmPackaging efficiency30-60 loads/H available. (Option: or 20-40 loads/H)Arm speed0-25rpm frequency control.

Contact Now

Control systemPLC control systemPhoto eye pallet height sensor3-12 RPM variable turntable speed by frequency changerTurntableGo home position after wrap cycle finishedSoft start/soft stopHeavy duty chain driveFilm carriagePowered pre-stretch system to 300% to min film consumptionFilm delivery barlable speed by spparate AC Drive MotorHeavy duty double-chain carriage lift, calm and safetyTechnology DataMax load size(mm): 1200(L)X1200(W)X2400(H)Turntable dia: 1650mmTurntable Height: 77mmTurntable weight capacity: 2000kgsTurntable speed: 3-12rpmElectrics: 220V 50HZ 1 phasePower: 1.5KWPacking

Contact Now