Technical specification MWS Robot PRS MachineDrive speed robot: 1-4 m/min.Max. speed wrapper :90 m/minTotal weight:approx.

Contact Now

Capacity of tissue machine8rolls/HBearing capacity:Max. 10tons (including spool shaft)Working time:24Hours /7 daysPaper roll diameter:φ1000-3500mmPaper roll width:±3700mmMax. Width including spool shaft:±5800mmTravel distance:±2*200m straight + 2*15m cross directionTravel speed:Max. 40m/min (loaded)Max.

Contact Now

Capacity of tissue machine8rolls/HBearing capacity:Max. 10tons (including spool shaft)Working time:24Hours /7 daysPaper roll diameter:φ1000-3500mmPaper roll width:±3700mmMax. Width including spool shaft:±5800mmTravel distance:±2*200m straight + 2*15m cross directionTravel speed:Max. 40m/min (loaded)Max.

Contact Now

No.ItemBrandOrigin1PLC & touch screenSiemensGermany2InverterSchneiderFrance3Proximity switchOmronJapan4Limit switchOmronJapan5Power switchSchneiderFrance6RelayOmronJapan7PhotoeyePanasonicJapan8Pneumatic partsAirtecRodless cylinder: SMCTaiwan, ChinaJapan9MotorChinese brandChinaallet dimension: L1200mm * W1200mm * H1800mmVolt: 380Volts, 50Hz, 3 phaseTop sheet length: adjustable according to the pallet (normally 1200mm+2*300mm)Sheet delivery speed: 9.5m/minFilm feeding frame moving speed: 4.5m/minSheet cutting: knife blade, pneumatic drivenFilm roll width: Max.

Contact Now

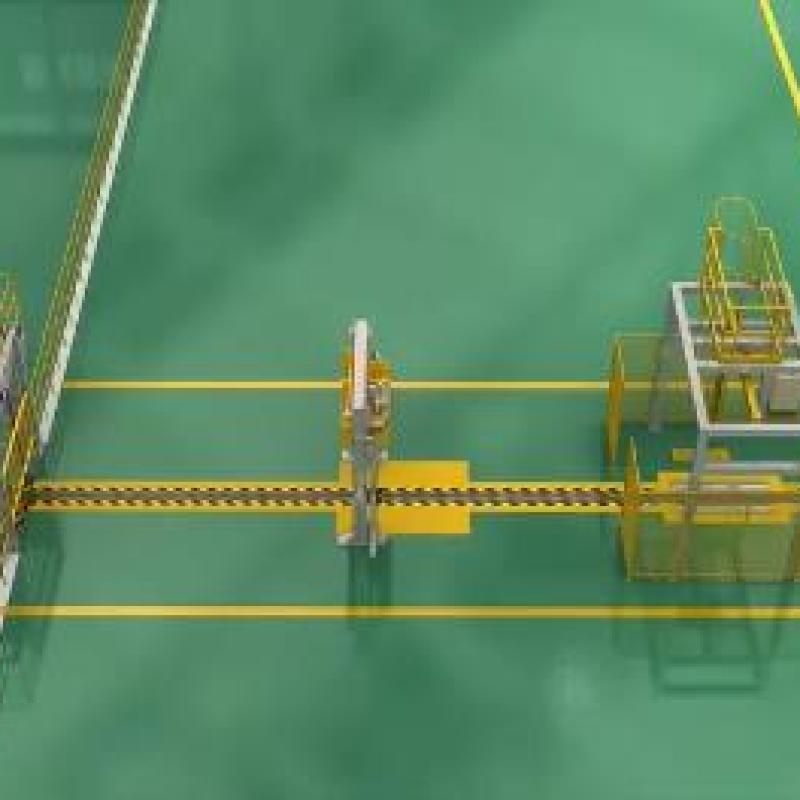

Voltage220/380V 50/60HZ 3PWrapping Size(L*W mm)(500-1100)*(500-1200)Wrapping Height500-1800/2400Capacity20-40 Pallet/HourTurntable size2000mmTurntable Height400mmIntelligent Conveying and Packaging System Paper Roll Conveying and Packaging System in Papermaking Completion Section. Paper roll conveying and packaging system is mainly used for paper roll conveying and packaging in paper mills. Use special machinery and advanced control system to complete automatic and manual conveying, stopping, turning, weighing, code spraying, labeling, turning and packaging of paper rolls.

Contact Now

Capacity of tissue machine8rolls/HWorking time:24Hours /7 daysPaper roll diameter:φ1000-3500mmPaper roll width:±3700mmMax. Width including spool shaft:±5800mmTravel distance:±2*200m straight + 2*15m cross directionSimple and reliable design, stable workingAutomatic feeding, welding, cutting strap, make a flat and beautiful weldSide Motor drive moves on the two parallel rails, which keeps right strap position.One automatic wear sword slot can cross the center of turntable.

Contact Now

Capacity of tissue machine8rolls/HBearing capacity:Max. 10tons (including spool shaft)Working time:24Hours /7 daysPaper roll diameter:φ1000-3500mmPaper roll width:±3700mmMax. Width including spool shaft:±5800mmTravel distance:±2*200m straight + 2*15m cross directionTravel speed:Max. 40m/min (loaded)Max.

Contact Now

ItemsSpecificationsRoll Diameter600-3000mmRoll width500-1800mmRoll WeightMax. 3000kgsPacking efficiency20-30 rolls/hTurntable diameter2200mmTurntable speed3-12rpmTurntable height490mm/710mmMachine weight1180kgPower supply2.2kw, 220V, 1P, 50 Hz Reel Wrapping Machine is the cylindrical winding packaging machine for cylindrical objects to carry out axial packaging to achieve the overall package. The wrapper wraps reel in 360 degree and can be designed with top platen device.

Contact Now

Capacity of tissue machine8rolls/HBearing capacity:Max. 10tons (including spool shaft)Working time:24Hours /7 daysPaper roll diameter:φ1000-3500mmPaper roll width:±3700mmMax. Width including spool shaft:±5800mmTravel distance:±2*200m straight + 2*15m cross directionTravel speed:Max. 40m/min (loaded)Max. 60m/min (unloaded)Paper roll conveyor system--V-type slat conveyor1. The V type is especially made for the paper roll.2. The v-slat conveyor is usually used in the paper roll packing and transporting system.3.

Contact Now

Gram weight:100g/m2Moisture:7%Mechanical performance:Suitable for non-tear rolled edgeWrapping crimping distance:100mmFolding side width:100mm every sideMain material of the frame: Q235-AThe surface of the 7 paper guide rollers is galvanized with a diameter of Ф100mm.4 sets of tension controller, using motor frequency control.4 sets of paper holder pneumatic clamping mechanism, including 8 cylinders.4 pneumatic control boxes and pneumatic control components used.Compressed air lines, fittings and accessories used inside the packaging machine.The gas point is connected to the gas point by the b

Contact Now

ItemSpecificationwrapping size(mm)500-1200mm (L)×500-1100(W)Wrapping height (mm)2200mmPacking efficiency20-40 loads / hourTurntable turning speed0-15rpm (Adjustable, soft start&stop)Roller conveying speed:20mpm adjustableTurntable diameter1800mmHeight of turntableTo be designed based on customer requirementsPower supply2.4KW 380V 50HZ 3PhaseMax. load capacity1500kgsPowered pre-stretch system up1:3.5 to min film consumption(Pre-stretch ratio can be specially made )2.Carriage door opens for effortless roll change and thread film3.

Contact Now

PP strap width9, 12, 15, 19mm, thickness 0.8mmPP strap splicing:electrical hot melt splicing,Splicing position580mm high above the conveyor. The pallet should not be less than 700mm in heightStrapper methodthe main machine move stroke is 400mm, mechanical sword strappingPlug between main control cabinet and wrapper for easier installation and maintenance.

Contact Now

Chain pitchP = 63.5 mmSlat widthB = 55 mmSlat lengthL = 250 mmThicknessS = 8 mm Stainless steel 304Turntable diameterDesign based on paper reel sizeAfter finishing stretch wrapping, the film tail will be cut and next film head is clamped automatically. Air blowing to wrap film head into pallet.Hot cutting wire to cut the film after wrapping, and then wiper arm brush against film tail.

Contact Now

No.ItemBrandOrigin1PLC & touch screenSiemensGermany2InverterSchneiderFrance3Proximity switchOmronJapan4Limit switchOmronJapan5Power switchSchneiderFrance6RelayOmronJapan7PhotoeyePanasonicJapan8Pneumatic partsAirtecRodless cylinder: SMCTaiwan, ChinaJapan9MotorChinese brandChinaPallet dimension: L1200mm * W1200mm * H1800mmVolt: 380Volts, 50Hz, 3 phaseTop sheet length: adjustable according to the pallet (normally 1200mm+2*300mm)Sheet delivery speed: 9.5m/minFilm feeding frame moving speed: 4.5m/min

Contact Now

ItemSpecificationsStrapping widthMax. 1200mmStrapping heightMax.

Contact Now

Max load size(mm)1200 (L)×1200(W)×1600(H)mmPacking efficiency20-40 loads / hourRotary arm speed3-15rpmHeight of turntable500mm±100mmPower supply380V 60HZ 3PhaseMax load capacity2000kgsWrapping requirementBottom wrapping up to 2/3 of pallet, top wrapping 15cm higher than the height of palletWorking ambianceIndoor, normal temperatureTurntableDiameter: 2000mmMast heightAccording to the pallet and turntable heightFilm carriagePowered pre-stretch system up to 300% to min film consumption(Prestretch ratio can be specially made)Carriage door opens for effortless roll change and thread filmFilm delive

Contact Now

Technical specificationsV-type slat conveyor Chain pitch: P = 63.5 mm Slat width: B = 55 mm Slat length: L = 250 mm Thickness: S = 8mm, Stainless steel, or carbon steel Length of conveyor Customized No.

Contact Now

Technical specificationsV-type slat conveyor Chain pitch: P = 63.5 mm Slat width: B = 55 mm Slat length: L = 250 mm Thickness: S = 8mm, Stainless steel, or carbon steel Length of conveyor Customized No.

Contact Now

No.ItemBrandOrigin1PLC & touch screenSiemensGermany2InverterSchneiderFrance3Proximity switchOmronJapan4Limit switchOmronJapan5Power switchSchneiderFrance6RelayOmronJapan7PhotoeyePanasonicJapan8Pneumatic partsAirtecRodless cylinder: SMCTaiwan, ChinaJapan9MotorChinese brandChinaThe cease sorting deck is composed through the 12 unit.

Contact Now

ItemSpecificationWrapping specifications(500-1300)mm*(500-1200)mm.Packing height2400mmPackaging efficiency30-60 loads/H available.

Contact Now

ItemSpecificationWrapping specifications(500-1300)mm*(500-1200)mm.Packing height2400mmPackaging efficiency30-60 loads/H available.

Contact Now

Material: stretch filmWidth: 500mmThickness: 17-35μmInner Core: 76.2mmOuter-Dia.: ≤260 mmOpen-door type pre-stretch film carriage, stretch ratio 250% (1m to 3.5m)Film carriage lifting driving: chain driving, good stability and high reliability Driving reducer: worm gear reducer; Motor power: 0.75kw, SEW

Contact Now

Material: stretch filmWidth: 500mmThickness: 17-35μmInner Core: 76.2mmOuter-Dia.: ≤260 mm Specification2.1 Strapping specification:Size of pallet: 1300mmx1300mmx2000mm2.2 Requirement for the placing of the pal

Contact Now