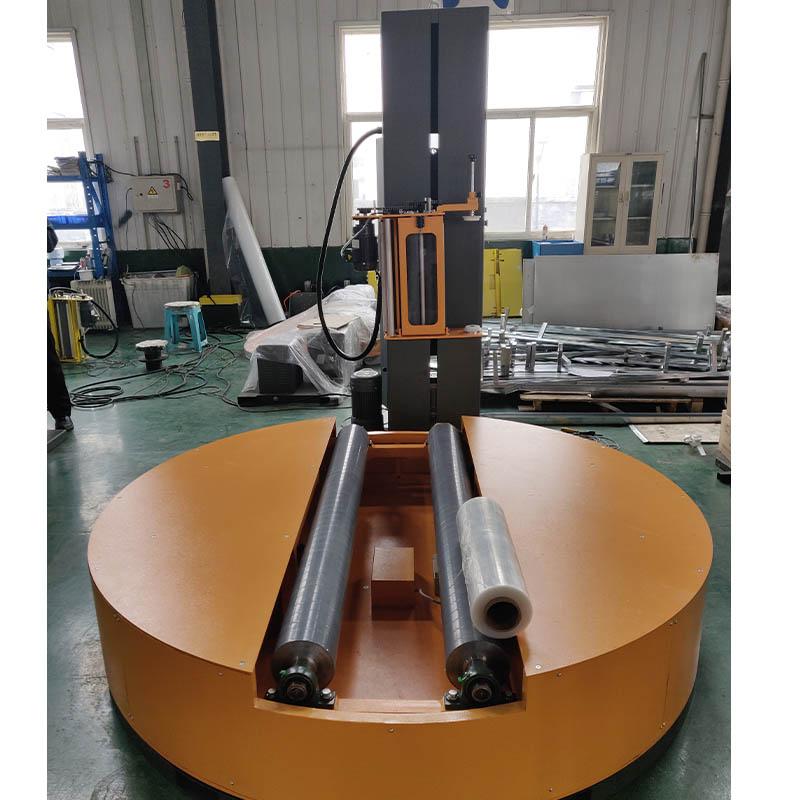

ItemsSpecificationsRoll Diameter600-1500mmRoll width500-1600mmRoll WeightMax. 2000kgsPacking efficiency20-30 rolls/hTurntable diameter2000mmTurntable speed3-12rpmTurntable height490mm/710mmMachine weight1080kgPower supply2.2kw, 220V, 1P, 50 HzMachine dimension2895(L) ×2000(W) ×2300(H) mmOption:Auto eject the reel after wrapping progressTop platen device;Slewing bearing can be equipped with.Is conducive to the storage, transport and turnover of goods, with dust, moisture, cleaning the role of. Its packaging cost low, high efficiency, improve the level of packaging.

Contact Now

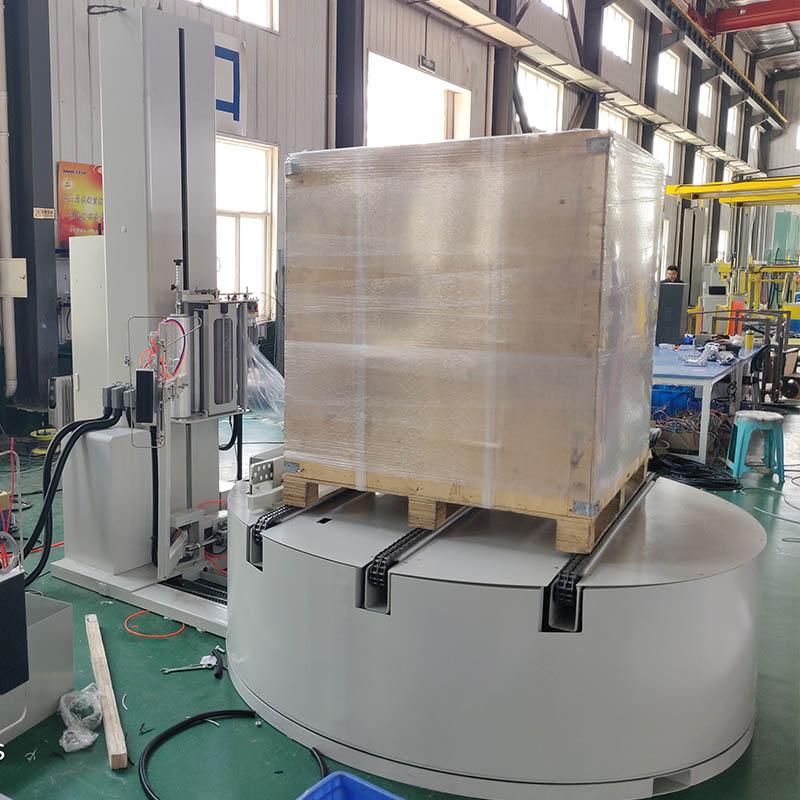

Technical specifications ItemSpecificationWrapping size500-1300mm (L) *500-1300mm (W)Packaging heightMax.2400mm (1800/2800/3200mm available)Work efficiency20-40 loads/HTurntable speed0-12RPM (adjustable, soft start & stop)BearingMax. 2000kgsTurntable sizeD=1650mm, H=78mmFilm carriageDriven pre-stretch carriage, move up and down on side of the towerStretch ratioUp to 1:2.5TowerDouble chain design.

Contact Now

ItemsSpecificationsRoll Diameter600-3000mmRoll width500-1800mmRoll WeightMax. 3000kgsPacking efficiency20-30 rolls/hTurntable diameter2200mmTurntable speed3-12rpmTurntable height490mm/710mmMachine weight1180kgPower supply2.2kw, 220V, 1P, 50 Hz Reel Wrapping Machine is the cylindrical winding packaging machine for cylindrical objects to carry out axial packaging to achieve the overall package. The wrapper wraps reel in 360 degree and can be designed with top platen device.

Contact Now

ItemsSpecificationsRoll Diameter600-1800mmRoll width500-2250mmRoll WeightMax.

Contact Now

Package length≤2200mmPackage diameter400mmCross section of goods(W×H)550X550mmPackaging speed4-6m/minPackaging efficiency40-60s/pieceOperation voltage380V.50HzMain engine power3.5KWPackaging material materialStretch film, anti rust composite paper, woven tape, aluminum plastic film, etcPacking material inner diameterΦ38,Φ50,Φ75Outer diameter of packaging materialsΦ150-Φ600Packaging material width50-120mmSwivel travelThe lifting stroke is 250mm; Horizontal movement 400mmAutomatic winding mechanism /ZSPneumatic controlPneumatic roof pressure /CSOptionalPneumatic roller protector /HGOptionalConve

Contact Now

Chain pitchP = 63.5 mmSlat widthB = 55 mmSlat lengthL = 250 mmThicknessS = 8 mm Stainless steel 304Turntable diameterDesign based on paper reel sizeThe photoelectric switch is installed on the film carriage, automatic detect the height of the pallet

Contact Now

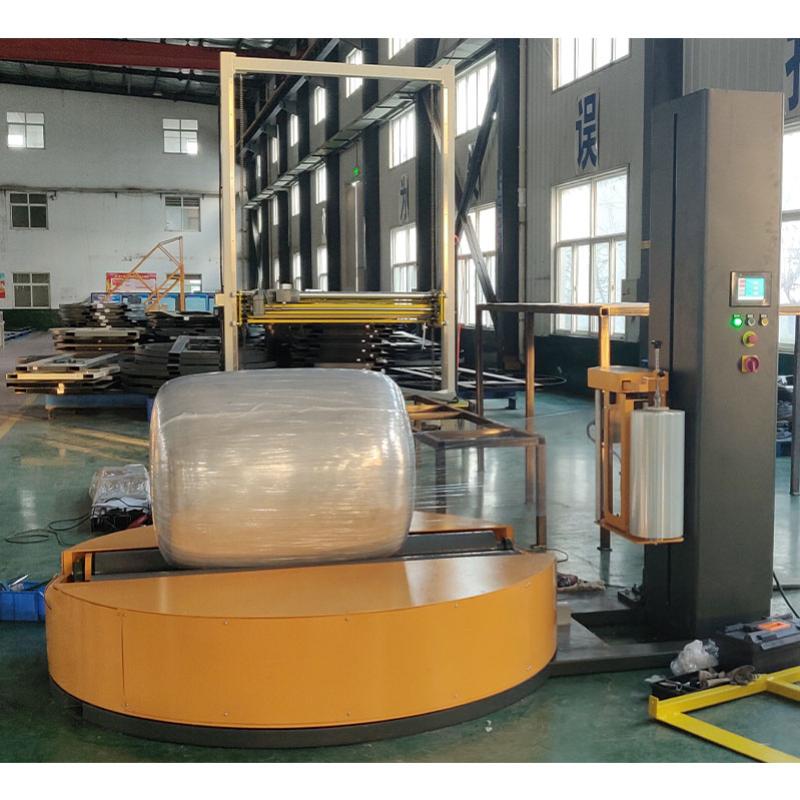

Product ParametersTurntable Diameter1650 mmWrapping Height Max.2500 mmLoad Capacity2000 kgEfficiency20 - 40 loads/hTurntable Height85 mmTurntable Speed0 - 12 rpm, variablePre-StretchPowered Roller Pre-Stretch System Up to 250 - 300%Voltage220 VAC 1 ph 50/60 HzPower1.55 kwMachine SizeL 2550 mm × W 1650 mm × H 2485 mm 300% Pre-stretch rate, save 30% film compared to traditional pallet wrapping machine.

Contact Now

Packing Size Max.W 500 - 1200 mm × L 500 - 1200 mmTurntable Diameter1650 mmWrapping Height Max.2500 mmLoad Capacity2000 kgEfficiency20 - 40 loads/hTurntable Height85 mmTurntable Speed0 - 12 rpm, variablePre-StretchPowered Roller Pre-Stretch System Up to 250 - 300%Stretch FilmLLDPE Stretch Film in 500 mm width × 15 - 35 um thickness; Film Reel in 76 mm core diameter × Max.

Contact Now

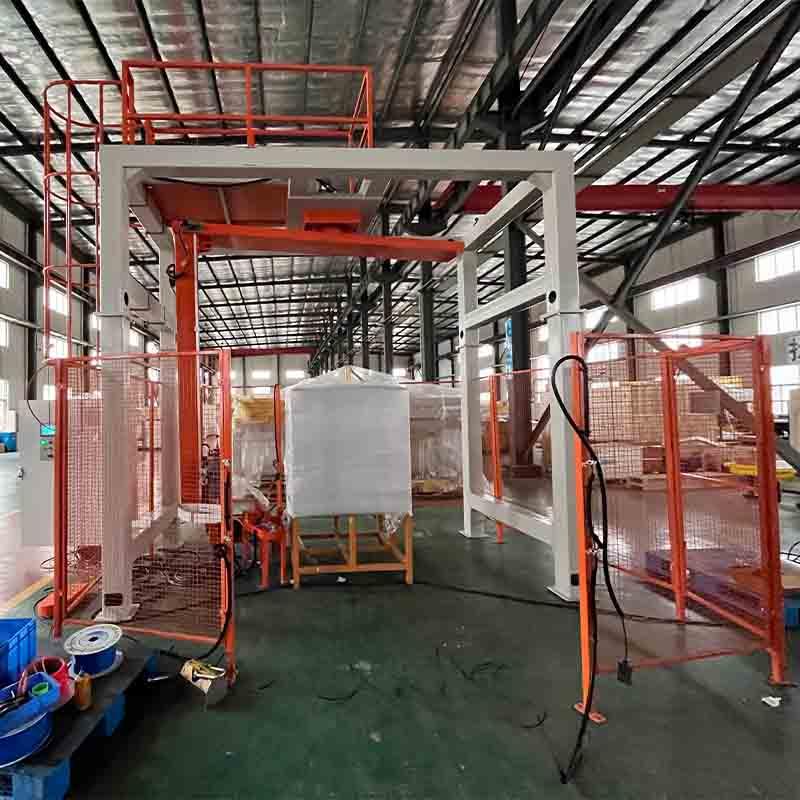

Wrapping speed:30-60pallets/hRotating speed of the rotary arm:0-35rpm, variable frequency control motor drivingFunction of rotary arm:automatic brake system, automatic resetFilm carriage:pre-stretch film carriagethe stretch ratio up to 250%automatic stretch film feedingFilm lifting guide rail: double chain structure, the lifting speed adjustableControl system: PLC control system, wrapping layers and times adjustableAutomatic height detection of the goodsAuto film feeding: pneumatic dr

Contact Now

Product ParametersModelSCR1800FR-PLVoltage380V 50HZ 3PPowerTurntable Motor: 1.5kw, Film Motor: 0.4kw, Column Motor: 0.55kwWrapping Size(L*W mm)(500-1100)*(500-1200)Wrapping Height500-1800Capacity35-45 Pallet/HourSpeedAdjustableMachine Size4200*2200*3500mmGood Price Intelligent Fully Automatic Rotating Arm Pallet Wrapper.There are two types of arm winding machine, one is stand-alone version , the other is online version . Both are suitable for larger and heavier products. It is inconvenient to use tray winding machine.

Contact Now

Chain pitchP = 63.5 mmSlat widthB = 55 mmSlat lengthL = 250 mmThicknessS = 8 mm Stainless steel 304Turntable diameterDesign based on paper reel sizeAfter finishing stretch wrapping, the film tail will be cut and next film head is clamped automatically. Air blowing to wrap film head into pallet.Hot cutting wire to cut the film after wrapping, and then wiper arm brush against film tail.

Contact Now

ItemSpecificationTurntable speed0-12RPM (adjustable, soft start & stop)BearingMax. 2000kgsStretch ratioUp to 250%TowerDouble chain design. Lifting speed adjustableControl systemPLCRemarks: Some parts of the machine can be exchanged according to customer requirements.Option I: Standard low profile ramp.Option II: Weight scaleThe wrapping recognise dust-proof, moisture-proof, much less packaging cost, enhance packing efficiency, and decrease product loss in transportation.

Contact Now

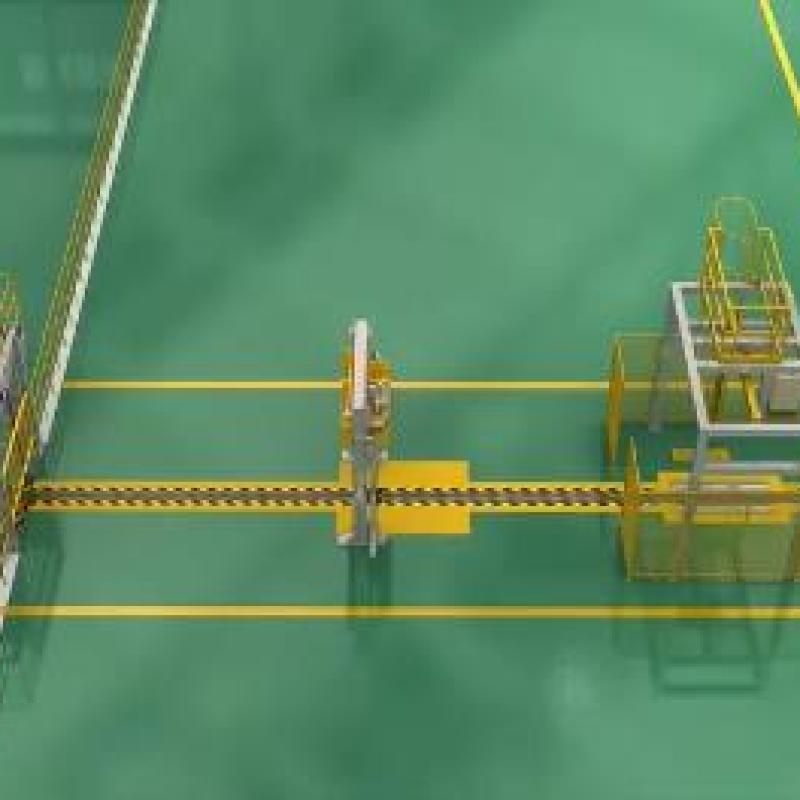

SpecificationsModelUCR-T2000APacking Size Max.W 1200 mm × L 1200 mmWrapping Height Max.2000 mmTurntable Diameter2000 mmLoad Capacity2000 kgEfficiency40 - 60 loads/hFilm Delivery SystemPowered Roller Pre-Stretch System Up to 250 - 300%Turntable Height470 mmTurntable Rotation Speed0 - 12 rpm, variableRoller Table Width (BF)1300 mmConveyor Speed8 m/min, ConstantAutomatic Film Clamper and CutterStd.Stretch FilmLLDPE Stretch Film in 500 mm width × 15 - 35 um thickness; Film Reel in 76 mm core diameter × Max.

Contact Now

Material: stretch filmWidth: 500mmThickness: 17-35μmInner Core: 76.2mmOuter-Dia.: ≤260 mmOpen-door type pre-stretch film carriage, stretch ratio 250% (1m to 3.5m)Film carriage lifting driving: chain driving, good stability and high reliability Driving reducer: worm gear reducer; Motor power: 0.75kw, SEW

Contact Now

ModelT1650F Automatic pre-stretch film wrapping machineWrapping product sizeL(500-1200) mm × W(500-1200)mmWrapping heightL type:1800mm H type:2400mm Y type:2800mmPacking efficiency20-40 pallet/hRotary speed0~15rpm rotary speed, adjustable, steady start and stopTurntable sizeDia:1650mm Height:78mmTurntable weight capacity2000kgsFilm carriage systemPre-stretch film carriage, pre-stretch up to 250%,automatic transport filmUp and down uprightDouble chain structure, adjustable up and down speed by transducerControl systemPLC programmableMachine weight700kgMachi

Contact Now

ModelT1650F Automatic pre-stretch film wrapping machineWrapping product sizeL(500-1200) mm × W(500-1200)mmWrapping heightL type:1800mm H type:2400mm Y type:2800mmPacking efficiency20-40 pallet/hRotary speed0~15rpm rotary speed, adjustable, steady start and stopTurntable sizeDia:1650mm Height:78mmTurntable weight capacity2000kgsFilm carriage systemPre-stretch film carriage, pre-stretch up to 250%,automatic transport filmUp and down uprightDouble chain structure, adjustable up and down speed by transducerControl systemPLC programmableMachine weight700kgMachi

Contact Now

Rotating speed of the rotary arm:0-35rpm, variable frequency control motor drivingFunction of rotary arm:automatic brake system, automatic resetFilm carriage:pre-stretch film carriagethe stretch ratio up to 250%automatic stretch film feedingFilm lifting guide rail: double chain structure, the lifting speed adjustableControl system: PLC control system, wrapping layers and times adjustableAutomatic height detection of the goodsAuto film feeding: pneumatic driving, auto film feeding, aut

Contact Now

Technical SpecificationItemsSpecificationsWrapping sizeDiameter (200-600mm);Width (200-500mm)Packing efficiency20-40 rolls/hourTurntable speed0-12 rpmFilm carriagePower pre-stretch film carriagePre-stretch ratio1:2.5 or customizedTurntable height700mmTurntable capacity80kgPower supplyAC 220V/ 60Hz/ 1Phase, 0.8kwMachine size (L*W*H)1460mm*840mm*1492mmMachine weight200kgs2017.3 Shandong Sinolion Machienry Corp. Ltd start expanding the new plant.2015.9 Shandong Sinolion Machinery Corp.

Contact Now

Product DescriptionControl systemPLC control systemPhoto eye pallet height sensor3-12 RPM variable turntable speed by frequency changerTurntableGo home position after wrap cycle finishedSoft start/soft stopHeavy duty chain driveFilm carriagePowered pre-stretch system to 300% to min film consumptionFilm delivery barlable speed by spparate AC Drive MotorHeavy duty double-chain carriage lift, calm and safetyTechnology DataMax load size(mm): 1200(L)X1200(W)X2400(H)Turntable dia: 1650mmTurntable Height: 77mmTurntable weight capacity: 2000kgsTurntable speed: 3-12rpmElectrics: 220V 50HZ 1 phase

Contact Now

Wrapping product size(500~1300)mm×(500~1200)mmWrapping height1800/2600mmWrapping efficiency30-60 piece/hRotary arm speed0~15rpm,0~25rpm,0~35rpm transducer adjustableRotary arm capacityhigh sensitive emergency stop system, rotary arm automatic re-backCarriage systemPre-stretch film carriage, up to 250%, automatic transporting film, speed is adjustableAutomatic install and cut film deviceAutomatic clamping, cut film, automatic without workerControl systemPLC programme, wrapping layer & times is adjustable, automatic sensor goods heightSafety protectAlarm and protect net

Contact Now

Wrapping specification(500-1300)mm*(500-1200)mm.Packing height Standard 2400mm.Packaging efficiency30-60 loads/H availiable.Arm speed 0-15rpm, 0-25rpm frequency control.Arm performance High sensitivity emergency brake system, the arm automatically reset.Film carriage systemPre-stretch film carriage, ratio up to 300%, automatic film feeding & cutting device adjustable speed.Arm Chain structure, speed variable frequency adjustable.Control systemPlC programmable control, wrapping layer adjustable.

Contact Now

1. Wrapping size500-1200mm (L) *500-1200mm (W)2. Packaging heightMax.2400mm (1800/2800mm availiable)3. Work efficiency20-40 loads/H4. Turntable speed0-12RPM (adjustable, soft start & stop)5. BearingMax. 2000kgs6. Turntable sizeD=1650mm, H=76mm7. Film carriagemotorised pre-stretch8. TowerDouble chain design. Lifting speed adjustable 9. Control systemPLC10. Weight600kgs11.

Contact Now

1. Wrapping size500-1200mm (L) *500-1200mm (W)2. Packaging heightMax.2400mm (1800/2800mm availiable)3. Work efficiency20-40 loads/H4. Turntable speed0-12RPM (adjustable, soft start & stop)5. BearingMax. 2000kgs6. Turntable sizeD=1650mm, H=76mm7. Film carriagemotorised pre-stretch8. TowerDouble chain design. Lifting speed adjustable 9. Control systemPLC10. Weight600kgs11.

Contact Now

Control systemPLC control systemPhoto eye pallet height sensor3-12 RPM variable turntable speed by frequency changerTechnology DataMax load size(mm): 1200(L)X1200(W)X2400(H)Turntable dia: 1650mmTurntable Height: 77mmTurntable weight capacity: 2000kgsTurntable speed: 3-12rpmElectrics: 220V 50HZ 1 phasePower: 1.5KWControl systemPhoto-eye pallet height sensor0-3 top(bottom)&up-down wrap times choose3-12RPM variable turntable speed by frequency changerVariable carriage up/down speedCycle pause capability

Contact Now