ItemSpecificationWrapping specifications(500-1300)mm*(500-1200)mm.Packing height2400mmPackaging efficiency20-40 loads/H available.

Contact Now

ItemsSpecificationsRoll Diameter600-1800mmRoll width500-2250mmRoll WeightMax.

Contact Now

Max load size(mm)1200 (L)×1200(W) ×2000(H)mmPacking efficiency0-60 loads / hourRotary arm speed0-25rpmPower supply4.0KW 380V 50HZ 3PhaseMax load capacity2000kgsWrapping requirementBottom wrapping up to 2/3 of pallet, top wrapping 15cm higher than the height of palletWorking ambianceIndoor, normal temperatureStop the finishing rolls coming from the rewinder and releaserolls to the V-type slat conveyor according in order.Change the gap conveying into the continuos conveying.

Contact Now

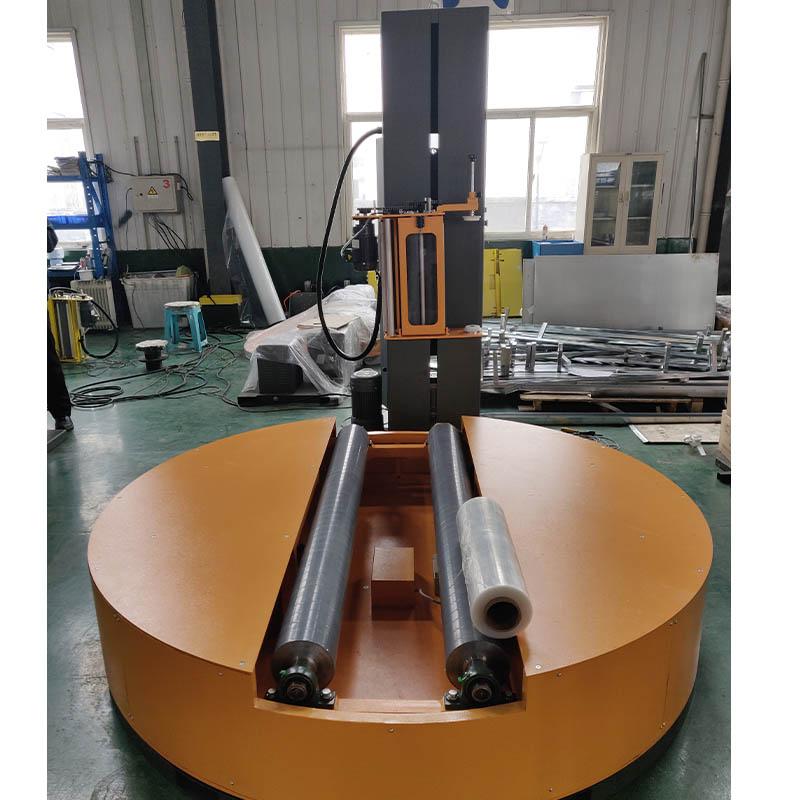

ModelT1650F Automatic pre-stretch film wrapping machineWrapping product sizeL(500-1200) mm × W(500-1200)mmWrapping heightL type:1800mm H type:2400mm Y type:2800mmPacking efficiency20-40 pallet/hRotary speed0~15rpm rotary speed, adjustable, steady start and stopTurntable sizeDia:1650mm Height:78mmTurntable weight capacity2000kgsFilm carriage systemPre-stretch film carriage, pre-stretch up to 250%,automatic transport filmUp and down uprightDouble chain structure, adjustable up and down speed by transducerControl systemPLC programmableMachine weight700kgMachi

Contact Now

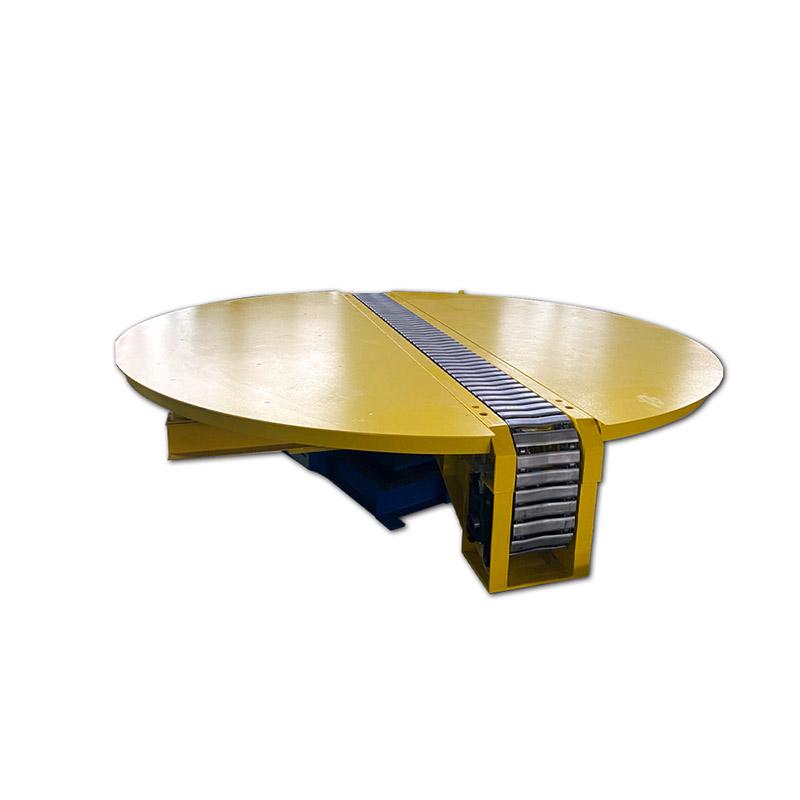

Max load size(mm)1200 (L)×1200(W)×1600(H)mmPacking efficiency20-40 loads / hourRotary arm speed3-15rpmHeight of turntable500mm±100mmPower supply380V 60HZ 3PhaseMax load capacity2000kgsWrapping requirementBottom wrapping up to 2/3 of pallet, top wrapping 15cm higher than the height of palletWorking ambianceIndoor, normal temperatureTurntableDiameter: 2000mmMast heightAccording to the pallet and turntable heightFilm carriagePowered pre-stretch system up to 300% to min film consumption(Prestretch ratio can be specially made)Carriage door opens for effortless roll change and thread filmFilm delive

Contact Now

Technical specificationsV-type slat conveyor Chain pitch: P = 63.5 mm Slat width: B = 55 mm Slat length: L = 250 mm Thickness: S = 8mm, Stainless steel, or carbon steel Length of conveyor Customized No.

Contact Now

Technical specificationsV-type slat conveyor Chain pitch: P = 63.5 mm Slat width: B = 55 mm Slat length: L = 250 mm Thickness: S = 8mm, Stainless steel, or carbon steel Length of conveyor Customized No.

Contact Now

Technical specificationsV-type slat conveyor Chain pitch: P = 63.5 mm Slat width: B = 55 mm Slat length: L = 250 mm Thickness: S = 8mm, Stainless steel, or carbon steel Length of conveyor Customized No.

Contact Now

ModelT1650F Automatic pre-stretch film wrapping machineWrapping product sizeL(500-1200) mm × W(500-1200)mmWrapping heightL type:1800mm H type:2400mm Y type:2800mmPacking efficiency20-40 pallet/hRotary speed0~15rpm rotary speed, adjustable, steady start and stopTurntable sizeDia:1650mm Height:78mmTurntable weight capacity2000kgsFilm carriage systemPre-stretch film carriage, pre-stretch up to 250%,automatic transport filmUp and down uprightDouble chain structure, adjustable up and down speed by transducerControl systemPLC programmableMachine weight700kgMachi

Contact Now

Technical specifications:Machine size:L5530×W2645×H3900 (mm)(max)Work efficiency:30 loads/H (wrapping and top-sheeting)Rotary speed: 15rpm Power supply:380Vac/3phases/50Hz, Air supply:0.5-0.6Mpa,Rotary arm stop by safety bumper and reflection photo eye sensing and obstacle in the rotating area.Powered pre-stretch system up to 250% to min film consumptionLifting unit in wrapping field will lift pallet up to 150mm above the roller conveyorFull auto feeding film and cutting film

Contact Now

Material: stretch filmWidth: 500mmThickness: 17-35μmInner Core: 76.2mmOuter-Dia.: ≤260 mmOpen-door type pre-stretch film carriage, stretch ratio 250% (1m to 3.5m)Film carriage lifting driving: chain driving, good stability and high reliability Driving reducer: worm gear reducer; Motor power: 0.75kw, SEW

Contact Now

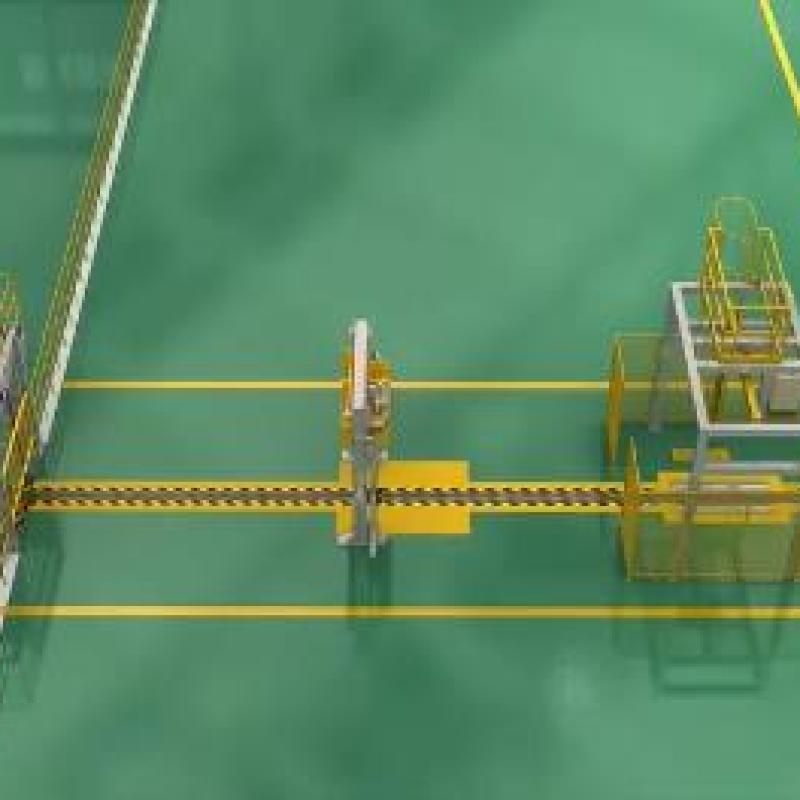

Product originShandong,ChinaSizeCustomizedDelivery time30daysSupply capacity1000sets/monthAuto Module Conveyor System is high efficient downstream and processing system for modern corrugated cardboard and carton box factory. Through the layout of the whole plant, a reasonable plan is designed to realize automatic cardboard conveying and reduce manpower and material resources

Contact Now

Capacity of tissue machine8rolls/HBearing capacity:Max. 10tons (including spool shaft)Working time:24Hours /7 daysPaper roll diameter:φ1000-3500mmPaper roll width:±3700mmMax. Width including spool shaft:±5800mmTravel distance:±2*200m straight + 2*15m cross directionTravel speed:Max. 40m/min (loaded)Max. 60m/min (unloaded)Paper roll conveyor system--V-type slat conveyor1. The V type is especially made for the paper roll.2. The v-slat conveyor is usually used in the paper roll packing and transporting system.3.

Contact Now

Chain pitch: P = 63.5 mm Slat width: B = 55 mm Slat length: L = 250 mm Thickness: S = 8mm, 16 Mn Steel Conveyor height 12000mm*5 sets+17500mm*1 set Conveyor height 800mm Speed of conveyors 18m/min (Can be adjusted or as required) Slat bearing,Gear motor Chinese brand Power 3kW+4kW (or as required)chain conveyer, chain pitch P=63.5mm,V-slat width:B=50mm,slat length:B=250mm,Thickness:S=8 mm,Material 16 manganese.2. Slat are being made V type to transport paper rolls with a 170-degree angle.3.

Contact Now

Gram weight:100g/m2Moisture:7%Mechanical performance:Suitable for non-tear rolled edgeWrapping crimping distance:100mmFolding side width:100mm every sideTechnical information1. Chain conveyer, chain pitch P=63.5mm, V-slat width: B=50mm, slat length: B=250mm, Thickness: S=8 mm, Material 16 manganese.2. Slat are being made V type to transport paper rolls with a 170-degree angle.3. Slat conveyor weight capacity: 3000kg/m...4. Bearings in roller of conveyor chain for running flexible and being greased through the space of the chain roller. Not often and no pollution.5.

Contact Now

Capacity of tissue machine8rolls/HWorking time:24Hours /7 daysPaper roll diameter:φ1000-3500mmPaper roll width:±3700mmMax. Width including spool shaft:±5800mmTravel distance:±2*200m straight + 2*15m cross directionSimple and reliable design, stable workingAutomatic feeding, welding, cutting strap, make a flat and beautiful weldSide Motor drive moves on the two parallel rails, which keeps right strap position.One automatic wear sword slot can cross the center of turntable.

Contact Now

ItemSpecificationWork efficiency20-40 loads/HTurntable speed0-12RPM (adjustable, soft start & stop)BearingMax. 2000kgsFilm carriageDriven pre-stretch carriage, move up and down on side of the towerStretch ratioUp to 250%TowerDouble chain design. Lifting speed adjustableControl systemPLCRemarks: Some parts of the machine can be exchanged according to customer requirements.Option I: Standard low profile ramp.Option II: Weight scaleSeparate start, reset and emergency stop buttons.Manual carriage up/down switch .Turntable jog button.

Contact Now

ItemSpecificationWrapping specifications(500-1300)mm*(500-1200)mm.Packing height2400mmPackaging efficiency20-40 loads/H available.

Contact Now

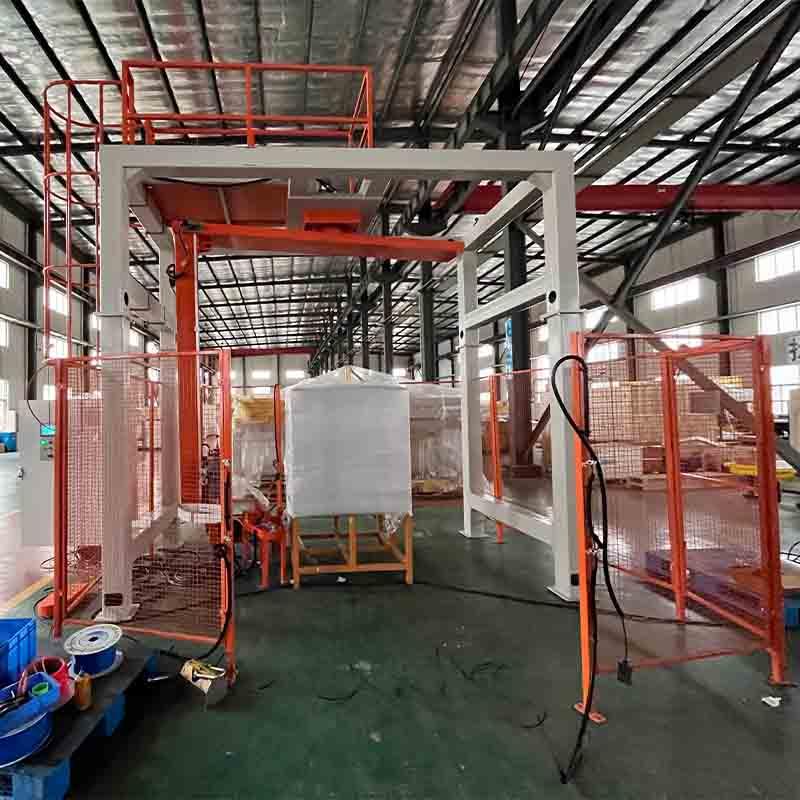

Wrapping size: L(500-1300)mm*W(500-1200)mmWrapping height:H(1800-2600)mmWrapping speed:30-60pallets/hRotating speed of the rotary arm:0-35rpm, variable frequency control motor drivingFunction of rotary arm:automatic brake system, automatic resetFilm carriage:pre-stretch film carriagethe stretch ratio up to 250%automatic stretch film feedingFilm lifting guide rail: double chain structure, the lifting speed adjustableControl system: PLC control system, wrapping layers and times adjustableAutomatic height detection of the goodsAuto film feeding: &

Contact Now

ItemSpecificationTurntable speed0-12RPM (adjustable, soft start & stop)BearingMax. 2000kgsStretch ratioUp to 250%TowerDouble chain design. Lifting speed adjustableControl systemPLCRemarks: Some parts of the machine can be exchanged according to customer requirements.Option I: Standard low profile ramp.Option II: Weight scaleThe wrapping recognise dust-proof, moisture-proof, much less packaging cost, enhance packing efficiency, and decrease product loss in transportation.

Contact Now

Max load size(mm)1200 (L)×1200(W) ×2000(H)mmPacking efficiency0-60 loads / hourRotary arm speed0-25rpmPower supply4.0KW 380V 50HZ 3PhaseMax load capacity2000kgsWrapping requirementBottom wrapping up to 2/3 of pallet, top wrapping 15cm higher than the height of palletWorking ambianceIndoor, normal temperatureSimple and reliable design, stable workingAutomatic feeding, welding, cutting strap, make a flat and beautiful weldSide Motor drive moves on the two parallel rails, which keeps right strap position.One automatic wear sword slot can cross the center of turntable.

Contact Now

Wrapping size: L(500-1300)mm*W(500-1200)mmWrapping height:H(1800-2600)mmWrapping speed:30-60pallets/hRotating speed of the rotary arm:0-35rpm, variable frequency control motor drivingFunction of rotary arm:automatic brake system, automatic resetFilm carriage:pre-stretch film carriagethe stretch ratio up to 250%automatic stretch film feedingFilm lifting guide rail: double chain structure, the lifting speed adjustableControl system: PLC control system, wrapping layers and times adjustableAutomatic height detection of the goodsAuto film feeding: &

Contact Now

Rotating ring inner diameter1200-2000mmWrapping dimensionWidth: 500-1100mm; Height: 500-1000mm; Length: 500-2000mmRotating ring speedMax. 30rpmCompressed air pressure0.5MpaAir consumption10L/MMotor powerrotating ring: 2.2kw 380V, 60HZ, 3phase ControlsOMRON PLC control systemPhoto-eye pallet height sensor0-7 separate top, bottom&up-down wrap count selectorsReinforce wrap allow more wrap on same locationFilm Tension Control adjustment on the panel3-15RPM variable arm speed by frequency changerSeparate variable carriage up/down speedCycle pause capability

Contact Now