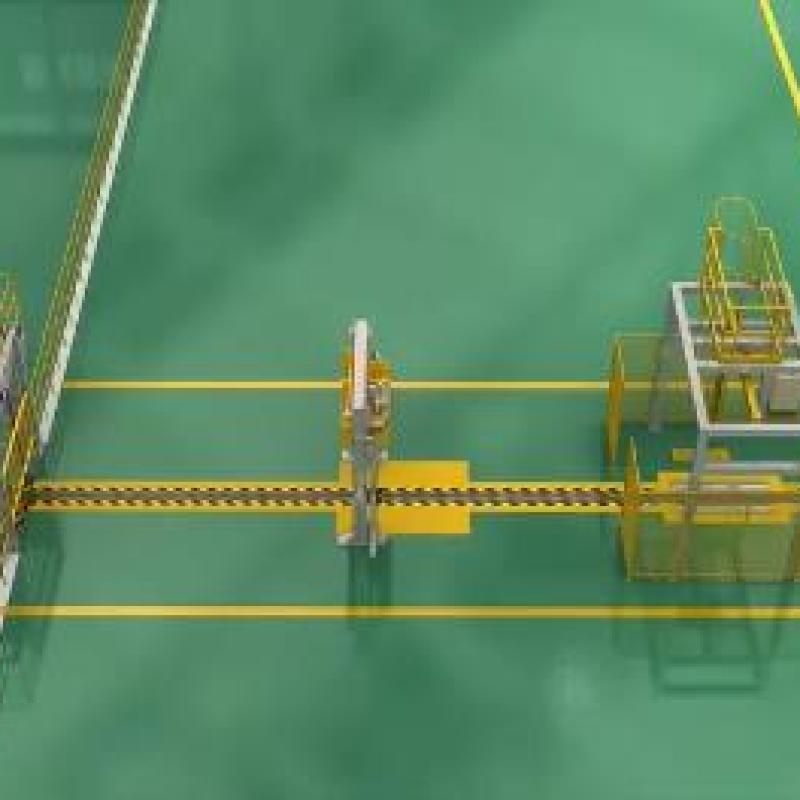

Product originShandong,ChinaSizeCustomizedDelivery time30daysSupply capacity1000sets/monthAuto Module Conveyor System is high efficient downstream and processing system for modern corrugated cardboard and carton box factory. Through the layout of the whole plant, a reasonable plan is designed to realize automatic cardboard conveying and reduce manpower and material resources

Contact Now

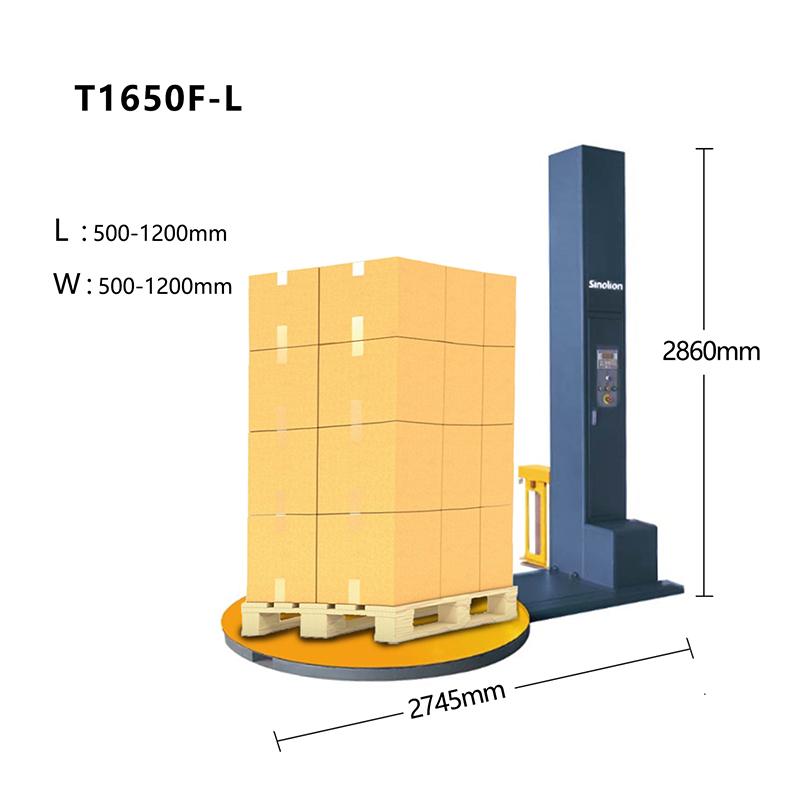

Voltage220/380V 50/60HZ 3PWrapping Size(L*W mm)(500-1100)*(500-1200)Wrapping Height500-1800/2400Capacity20-40 Pallet/HourTurntable size2000mmTurntable Height400mmIntelligent Conveying and Packaging System Paper Roll Conveying and Packaging System in Papermaking Completion Section. Paper roll conveying and packaging system is mainly used for paper roll conveying and packaging in paper mills. Use special machinery and advanced control system to complete automatic and manual conveying, stopping, turning, weighing, code spraying, labeling, turning and packaging of paper rolls.

Contact Now

Max load size(mm)1200 (L)×1200(W) ×2000(H)mmPacking efficiency0-60 loads / hourRotary arm speed0-25rpmPower supply4.0KW 380V 50HZ 3PhaseMax load capacity2000kgsWrapping requirementBottom wrapping up to 2/3 of pallet, top wrapping 15cm higher than the height of palletWorking ambianceIndoor, normal temperatureStop the finishing rolls coming from the rewinder and releaserolls to the V-type slat conveyor according in order.Change the gap conveying into the continuos conveying.

Contact Now

ItemSpecificationWrapping specifications(500-1300)mm*(500-1200)mm.Packing height2400mmPackaging efficiency20-40 loads/H available.

Contact Now

Max load size1200 L 1300W 2200H mmPacking efficiency 20-40 loads / hourArm speed 3-15rpmMachine weight 680kgPower supply 1.3KW 220V 50Hz 1Phase (standard)Material LLDPE Stretch FilmCore Diameter 76.2 mmFilm Width500 mmThe rotating parts of all driving parts are provided with protective cover. Automatic control system with emergency stop button to ensure safe production.

Contact Now

The moving parts on the equipment and the moving equipment must have safety protection measures. The protective covers and guardrails should be marked with eye-catching colors, and they should be fully protected and coordinated with the overall equipment.The safety of operators and maintenance personnel shall be fully considered in the design of equipment and electric control, and the control system shall have interlock protection function and necessary safety protection measures.2007 Land compensation in the development zone Suncun, plan and construct new production plant.

Contact Now

Capacity of tissue machine8rolls/HBearing capacity:Max. 10tons (including spool shaft)Working time:24Hours /7 daysPaper roll diameter:φ1000-3500mmPaper roll width:±3700mmMax. Width including spool shaft:±5800mmTravel distance:±2*200m straight + 2*15m cross directionTravel speed:Max. 40m/min (loaded)Max.

Contact Now

Product ParametersFrame material:carbon steel sheetSmall roller chain material:08B carbon steelRail material:steel rail.Sprocket material:steel matching standard sprocket (tooth surface quenching).Chain Tension:bearing housing tensionRoller material:60 carbon steel galvanized thickened roller,Conveyor line outer width/effective inner width:1450mm/1260mm (customized size according to cargo specifications) The conveying mechanism can adopt different forms such as rollers, belts, chain plates, etc.

Contact Now

Gram weight:100g/m2Moisture:7%Mechanical performance:Suitable for non-tear rolled edgeWrapping crimping distance:100mmFolding side width:100mm every sideTechnical information1. Chain conveyer, chain pitch P=63.5mm, V-slat width: B=50mm, slat length: B=250mm, Thickness: S=8 mm, Material 16 manganese.2. Slat are being made V type to transport paper rolls with a 170-degree angle.3. Slat conveyor weight capacity: 3000kg/m...4. Bearings in roller of conveyor chain for running flexible and being greased through the space of the chain roller. Not often and no pollution.5.

Contact Now

Capacity of tissue machine8rolls/HBearing capacity:Max. 10tons (including spool shaft)Working time:24Hours /7 daysPaper roll diameter:φ1000-3500mmPaper roll width:±3700mmMax. Width including spool shaft:±5800mmTravel distance:±2*200m straight + 2*15m cross directionTravel speed:Max. 40m/min (loaded)Max.

Contact Now

Feeding speed of the belt: 4.6m/sTension force, infinite regulation: 200-2500NHot melting sealing, length of sealing head: 27mmMaterial of belt: PET/PPWidth of belt: 9.5mm, 12.5mm,15.5mm Thickness of belt: 0.6-0.8mm The whole machine is equipped with automatic swords threading system.With the function of auto tape threading.The lifting of strapping heading is driven by gear motor SEW to ensure stable operation and reliable braking.With the strapping head of model VK10 K120-16 of TITAN Germany.

Contact Now

ItemData Rotating ring inner diameter1800mm Package dimension (W*H)100 mm*1200 mm Packing length>1200 mm Rotating ring speed20-30rpm Conveying speed5-8 m/min Packing material width 200 mm- 500 mm Power 2.2 Kw Machine Weight 1500 kg Machine shape size 2600 mm * 1650 mm *2600 mmFeatures: Siemens PLC electric control system, touch screen panelRing rotating speed controlled by the inverterIn-feed & out-feed conveyor speed controlled by the inverterStart and finish cycles are controlled by photocellsAuto film cutting and c

Contact Now

Technology specificationItemSpecificationBearingMax. 2000kgs or Max. 3000kgsTurntable sizeD=1650mm, H=78mmStretch ratio1:2, 1:2.5 or1:3.5TowerDouble chain design. Lifting speed adjustableControl systemPLCWeight600kgsRemarks: Some parts of the machine can be exchanged according to customer requirements.Option I: Standard low profile ramp.Option II: Weight scaleMore flexible for different pallet dimension;Film stretching mechanism with pallet dimension sensor for dimension adjustable;Automatic detect pallet height to decide wrap film length;

Contact Now

Technical dataItemSpecificationWrapping specifications(500-1300)mm*(500-1200)mm.Packing height2400mmPackaging efficiency30-60 loads/H available.

Contact Now

Control systemPLC control systemPhoto eye pallet height sensor3-12 RPM variable turntable speed by frequency changerTurntableGo home position after wrap cycle finishedSoft start/soft stopHeavy duty chain driveFilm carriagePowered pre-stretch system to 300% to min film consumptionFilm delivery barlable speed by spparate AC Drive MotorHeavy duty double-chain carriage lift, calm and safetyTechnology DataMax load size(mm): 1200(L)X1200(W)X2400(H)Turntable dia: 1650mmTurntable Height: 77mmTurntable weight capacity: 2000kgsTurntable speed: 3-12rpmElectrics: 220V 50HZ 1 phasePower: 1.5KWPacking

Contact Now

ItemSpecificationFilm carriageDriven pre-stretch carriage, move up and down on side of the towerTowerDouble chain design. Lifting speed adjustableControl systemPLCRemarks: Some parts of the machine can be exchanged according to customer requirements.Option I: Standard low profile ramp.Option II: Weight scaleKickerKick out the rolls to the required position or equipments.

Contact Now

Technical specificationsV-type slat conveyor Chain pitch: P = 63.5 mm Slat width: B = 55 mm Slat length: L = 250 mm Thickness: S = 8mm, Stainless steel, or carbon steel Length of conveyor Customized No.

Contact Now

1. The main frame, four robust columns connected by a solid construction consisting ofHeavy square cartridge profile, fully sprayed in RAL colour and designed for the most stable suspension of the swivel arm;2. Swivel arm from heavy cartridge profile fitted with external cabling for vertical movement of the slide which the foil trolley is suspended from. This slide is suspended from a chain and powered by a transmission motor. Fitted with frequency control3. · Automatic height sensor of the pallet load through a photo cell which is also able toDetect dark loads;4.

Contact Now

Technical specificationsV-type slat conveyor Chain pitch: P = 63.5 mm Slat width: B = 55 mm Slat length: L = 250 mm Thickness: S = 8mm, Stainless steel, or carbon steel Length of conveyor Customized No.

Contact Now

PP strap width9, 12, 15, 19mm, thickness 0.8mmPP strap splicing:electrical hot melt splicing,Splicing position580mm high above the conveyor. The pallet should not be less than 700mm in heightStrapper methodthe main machine move stroke is 400mm, mechanical sword strappingPlug between main control cabinet and wrapper for easier installation and maintenance.

Contact Now

No.ItemBrandOrigin1PLC & touch screenSiemensGermany2InverterSchneiderFrance3Proximity switchOmronJapan4Limit switchOmronJapan5Power switchSchneiderFrance6RelayOmronJapan7PhotoeyePanasonicJapan8Pneumatic partsAirtecRodless cylinder: SMCTaiwan, ChinaJapan9MotorChinese brandChinaThe cease sorting deck is composed through the 12 unit.

Contact Now

ItemSpecificationArm performancePrecise sensitivity emergency brake system; Automatic arm reset.Film carriage systemPre-stretch film carriage, stretch ratio up to 250% or 300%, automatic film feeding & cutting device, adjustable speed.Lifting columnChain structure, speed variable frequency adjustable.Control systemPLC programmable control; Wrapping layer adjustable;Automatic height sense.The design ideas and concepts of the equipment system and management system are advanced.

Contact Now

Capacity of tissue machine8rolls/HBearing capacity:Max. 10tons (including spool shaft)Working time:24Hours /7 daysPaper roll diameter:φ1000-3500mmPaper roll width:±3700mmMax. Width including spool shaft:±5800mmTravel distance:±2*200m straight + 2*15m cross directionTravel speed:Max. 40m/min (loaded)Max.

Contact Now

ItemSpecificationwrapping size(mm)500-1300mm (L)×500-1200(W)Wrapping height (mm)2200mmPacking efficiency20-40 loads / hourTurntable turning speed0-15rpm (Adjustable, soft start&stop)Roller conveying speed:18mpm adjustableTurntable diameter2000mmHeight of turntableTo be designed based on customer requirementsPower supply2.0KW 380V 50HZ 3PhaseMax. load capacity3000kgsAll equipment has high maintainability. There should be enough space for operation where the parts such as the motor and gearbox may be disassembled. Moving washer and protective cover.

Contact Now