Technical specifications ItemSpecificationWrapping specifications(500-1300)mm*(500-1200)mm.Packing height2400mm or produced based on actual conditionsPackaging efficiency30-60 loads/H available.

Contact Now

Function of rotary arm:automatic brake system, automatic resetFilm carriage:pre-stretch film carriagethe stretch ratio up to 250%automatic stretch film feedingFilm lifting guide rail: double chain structure, the lifting speed adjustableControl system: PLC control system, wrapping layers and times adjustableAutomatic height detection of the goodsAuto film feeding: pneumatic driving, auto film feeding, auto film cuttingPower supply:AC 380V/ 50HZSeparate safety circuit with Pilz CE certi

Contact Now

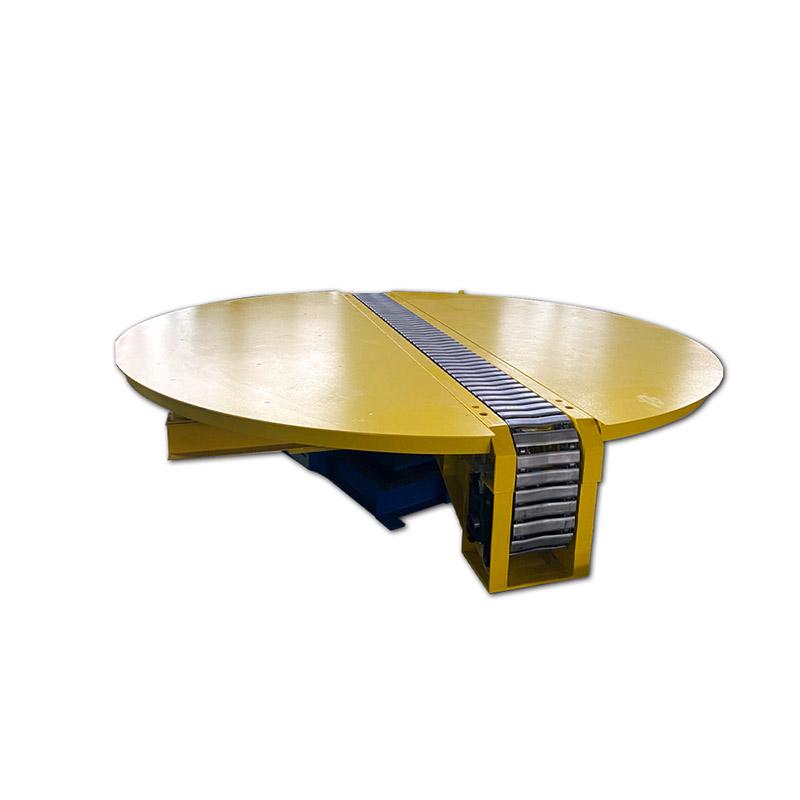

ItemSpecificationwrapping size(mm)500-1300mm (L)×500-1200(W)Wrapping height (mm)2200mmPacking efficiency20-40 loads / hourTurntable turning speed0-15rpm (Adjustable, soft start&stop)Roller conveying speed:18mpm adjustableTurntable diameter2000mmHeight of turntableTo be designed based on customer requirementsPower supply2.0KW 380V 50HZ 3PhaseMax.

Contact Now

ItemSpecificationFilm carriageDriven pre-stretch carriage, move up and down on side of the towerTowerDouble chain design. Lifting speed adjustableControl systemPLCRemarks: Some parts of the machine can be exchanged according to customer requirements.Option I: Standard low profile ramp.Option II: Weight scaleKickerKick out the rolls to the required position or equipments.

Contact Now

ItemSpecificationWrapping specifications(500-1300)mm*(500-1200)mm.Packing height2400mmPackaging efficiency30-60 loads/H available.

Contact Now

Max load size(mm)1200 (L)×1200(W) ×2000(H)mmPacking efficiency0-60 loads / hourRotary arm speed0-25rpmPower supply4.0KW 380V 50HZ 3PhaseMax load capacity2000kgsWrapping requirementBottom wrapping up to 2/3 of pallet, top wrapping 15cm higher than the height of palletWorking ambianceIndoor, normal temperatureUsed for the maintainer to climb to the top to do the maintenance.The safety guard fence can effectively protect the personal safety. The maintainer can stand on the maintenance platform to execute their work.

Contact Now

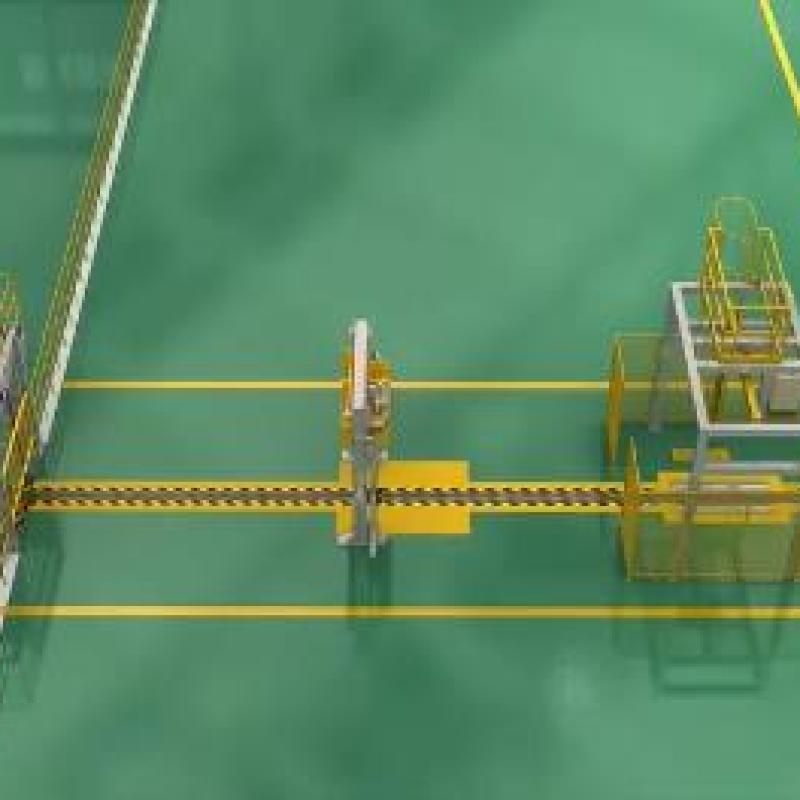

Product ParametersFrame material:carbon steel sheetSmall roller chain material:08B carbon steelRail material:steel rail.Sprocket material:steel matching standard sprocket (tooth surface quenching).Chain Tension:bearing housing tensionRoller material:60 carbon steel galvanized thickened roller,Conveyor line outer width/effective inner width:1450mm/1260mm (customized size according to cargo specifications) The conveying mechanism can adopt different forms such as rollers, belts, chain plates, etc.

Contact Now

ItemSpecificationwrapping size(mm)500-1200mm (L)×500-1100(W)Wrapping height (mm)2200mmPacking efficiency20-40 loads / hourTurntable turning speed0-15rpm (Adjustable, soft start&stop)Roller conveying speed:20mpm adjustableTurntable diameter1800mmHeight of turntableTo be designed based on customer requirementsPower supply2.4KW 380V 50HZ 3PhaseMax.

Contact Now

ItemSpecificationWrapping specifications(500-1300)mm*(500-1200)mm.Packing height2400mmPackaging efficiency30-60 loads/H available. (Option: or 20-40 loads/H)Arm speed0-25rpm frequency control.

Contact Now

Technical specifications ItemSpecificationWrapping specifications(500-1300)mm*(500-1200)mm.Packing height2400mm or produced based on actual conditionsPackaging efficiency30-60 loads/H available.

Contact Now

Palletizing speed400-1200 bags/hourLayers 1-10 layersAir supply 0.5-0.8 MpaPower supply380V/220V 50HZ+_10%Weight capacity(including mould)180-250kgRobtic palletizing and wrapping systems integrates palletzing, strapping, conveying and wrapping into automatic packing line with robot technology. It is widely applied in the industry of chemical , beverage,beer and other industries.It features with energy saving and high efficiency.

Contact Now

Technology specificationsItemSpecificationWrapping size500-1200mm (L) *500-1200mm (W)Packaging heightMax.2400mm (1800/2800mm available)Work efficiency20-40 loads/HTurntable speed0-12RPM (adjustable, soft start & stop)BearingMax. 2000kgsTurntable sizeD=1650mm, H=90mmFilm carriage in frontDriven pre-stretch carriage, move up and down on side of the towerStretch ratioUp to 300%TowerDouble chain design.

Contact Now

ItemSpecificationWork efficiency20-40 loads/HTurntable speed0-12RPM (adjustable, soft start & stop)BearingMax. 2000kgsFilm carriageDriven pre-stretch carriage, move up and down on side of the towerStretch ratioUp to 250%TowerDouble chain design. Lifting speed adjustableControl systemPLCRemarks: Some parts of the machine can be exchanged according to customer requirements.Option I: Standard low profile ramp.Option II: Weight scaleSeparate start, reset and emergency stop buttons.Manual carriage up/down switch .Turntable jog button.

Contact Now

ItemSpecificationWrapping size500-1050mm (L) *500-1050mm (W)Packaging heightMax.2200mm (2400/2800mm available)Work efficiency20-40 loads/HTurntable speed0-12RPM (adjustable, soft start & stop)BearingMax. 1000kgsTurntable sizeD=1500mm, H=78mmFilm carriageDriven pre-stretch carriage, move up and down on side of the towerStretch ratioUp to 1:1.2, Friction stretchWeight600kgsDimension2745mm*1500mm*2660mmFilm carriage on the front of the tower Open-door pre-stretch standard film carriage.

Contact Now

ItemSpecificationWrapping size500-1200mm (L) *500-1200mm (W)Packaging heightMax.2400mm (1800/2800mm available)Work efficiency20-40 loads/HTurntable speed0-12RPM (adjustable, soft start & stop)BearingMax. 2000kgsTurntable sizeD=1650mm, H=78mmFilm carriageDriven pre-stretch carriage, move up and down on side of the towerStretch ratioUp to 150%TowerDouble chain design.

Contact Now

Technical specifications ItemSpecificationwrapping size(mm)500-1200mm (L)×500-1200(W)Wrapping height (mm)2200mmPacking efficiency20-40 loads / hourTurntable turning speed0-15rpm (Adjustable, soft start&stop)Roller conveying speed:20mpm adjustableTurntable diameter1800mmHeight of turntableTo be designed based on customer requirementsPower supply2.0KW 380V 50HZ 3PhaseMax.

Contact Now

Max load size(mm)1200 (L)×1200(W) ×2000(H)mmPacking efficiency0-60 loads / hourRotary arm speed0-25rpmPower supply4.0KW 380V 50HZ 3PhaseMax load capacity2000kgsWrapping requirementBottom wrapping up to 2/3 of pallet, top wrapping 15cm higher than the height of palletWorking ambianceIndoor, normal temperatureStop the finishing rolls coming from the rewinder and releaserolls to the V-type slat conveyor according in order.Change the gap conveying into the continuos conveying.

Contact Now

ItemSpecificationwrapping size(mm)500-1300mm (L)×500-1200(W)Wrapping height (mm)2200mmPacking efficiency20-40 loads / hourTurntable turning speed0-15rpm (Adjustable, soft start&stop)Roller conveying speed:18mpm adjustableTurntable diameter2000mmHeight of turntableTo be designed based on customer requirementsPower supply2.0KW 380V 50HZ 3PhaseMax. load capacity3000kgsAll equipment has high maintainability. There should be enough space for operation where the parts such as the motor and gearbox may be disassembled. Moving washer and protective cover.

Contact Now

Max load size(mm)1200 (L)×1200(W) ×2000(H)mmPacking efficiency0-60 loads / hourRotary arm speed0-25rpmPower supply4.0KW 380V 50HZ 3PhaseMax load capacity2000kgsWrapping requirementBottom wrapping up to 2/3 of pallet, top wrapping 15cm higher than the height of palletWorking ambianceIndoor, normal temperatureSimple and reliable design, stable workingAutomatic feeding, welding, cutting strap, make a flat and beautiful weldSide Motor drive moves on the two parallel rails, which keeps right strap position.One automatic wear sword slot can cross the center of turntable.

Contact Now

ItemSpecificationwrapping size(mm)500-1200mm (L)×500-1100(W)Wrapping height (mm)2200mmPacking efficiency20-40 loads / hourTurntable turning speed0-15rpm (Adjustable, soft start&stop)Roller conveying speed:20mpm adjustableTurntable diameter1800mmHeight of turntableTo be designed based on customer requirementsPower supply2.4KW 380V 50HZ 3PhaseMax. load capacity1500kgsPowered pre-stretch system up1:3.5 to min film consumption(Pre-stretch ratio can be specially made )2.Carriage door opens for effortless roll change and thread film3.

Contact Now

Rotating speed of the rotary arm:0-35rpm, variable frequency control motor drivingFunction of rotary arm:automatic brake system, automatic resetFilm carriage:pre-stretch film carriagethe stretch ratio up to 250%automatic stretch film feedingFilm lifting guide rail: double chain structure, the lifting speed adjustableControl system: PLC control system, wrapping layers and times adjustableAutomatic height detection of the goodsAuto film feeding: pneumatic driving, auto film feeding, aut

Contact Now

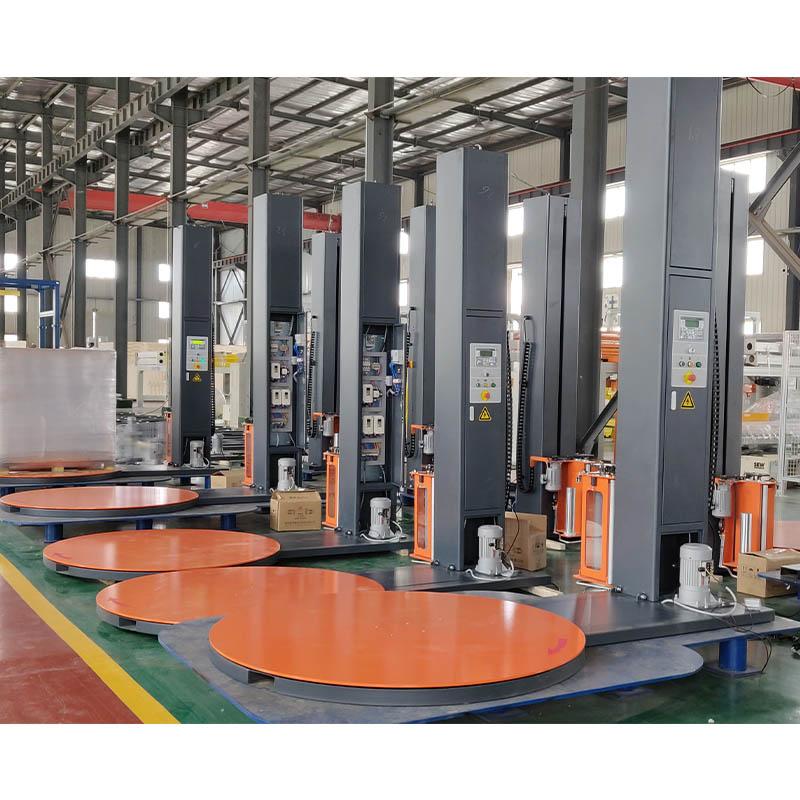

ItemSpecificationWrapping size500-1300mm (L) *500-1300mm (W)Packaging heightMax.2400mm (1800/2800mm available)Work efficiency20-40 loads/HTurntable speed0-12RPM (adjustable, soft start & stop)BearingMax. 2000kgsTurntable sizeD=1800mm, H=78mmFilm carriageDriven pre-stretch carriage, move up and down on side of the towerStretch ratioUp to 250%TowerDouble chain design.

Contact Now

Rotating ring inner diameter1200-2000mmWrapping dimensionWidth: 500-1100mm; Height: 500-1000mm; Length: 500-2000mmRotating ring speedMax. 30rpmCompressed air pressure0.5MpaAir consumption10L/MMotor powerrotating ring: 2.2kw 380V, 60HZ, 3phase ControlsOMRON PLC control systemPhoto-eye pallet height sensor0-7 separate top, bottom&up-down wrap count selectorsReinforce wrap allow more wrap on same locationFilm Tension Control adjustment on the panel3-15RPM variable arm speed by frequency changerSeparate variable carriage up/down speedCycle pause capability

Contact Now