ItemSpecificationWrapping specifications(500-1300)mm*(500-1200)mm.Packing height2400mmPackaging efficiency20-40 loads/H available.

Contact Now

The moving parts on the equipment and the moving equipment must have safety protection measures. The protective covers and guardrails should be marked with eye-catching colors, and they should be fully protected and coordinated with the overall equipment.The safety of operators and maintenance personnel shall be fully considered in the design of equipment and electric control, and the control system shall have interlock protection function and necessary safety protection measures.2007 Land compensation in the development zone Suncun, plan and construct new production plant.

Contact Now

Control systemPLC control systemPhoto eye pallet height sensor3-12 RPM variable turntable speed by frequency changerTurntableGo home position after wrap cycle finishedSoft start/soft stopHeavy duty chain driveFilm carriagePowered pre-stretch system to 300% to min film consumptionFilm delivery barlable speed by spparate AC Drive MotorHeavy duty double-chain carriage lift, calm and safetyTechnology DataMax load size(mm): 1200(L)X1200(W)X2400(H)Turntable dia: 1650mmTurntable Height: 77mmTurntable weight capacity: 2000kgsTurntable speed: 3-12rpmElectrics: 220V 50HZ 1 phasePower: 1.5KWPacking

Contact Now

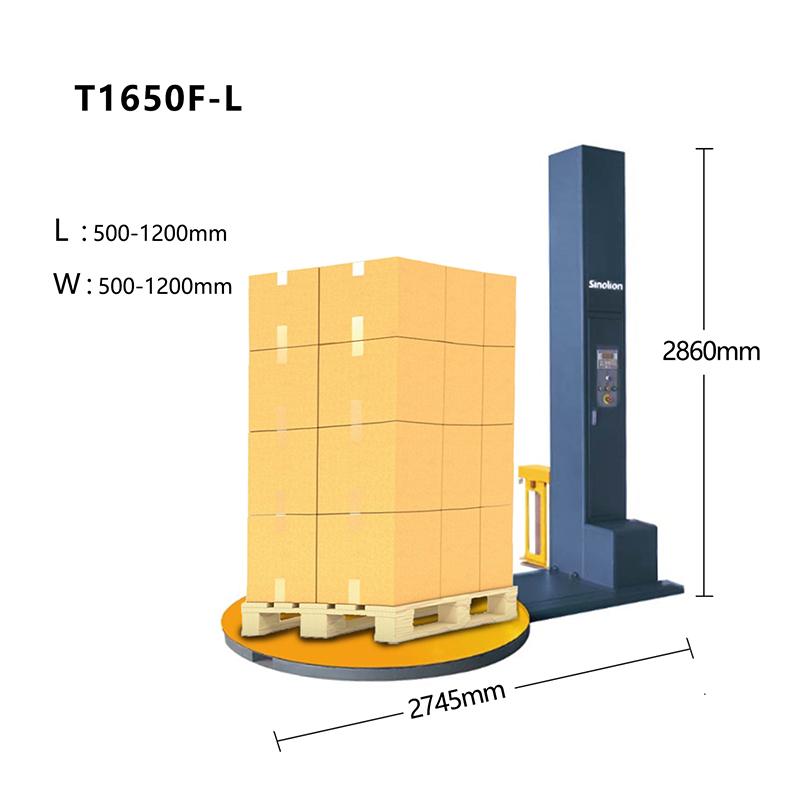

ModelT1650F Automatic pre-stretch film wrapping machineWrapping product sizeL(500-1200) mm × W(500-1200)mmWrapping heightL type:1800mm H type:2400mm Y type:2800mmPacking efficiency20-40 pallet/hRotary speed0~15rpm rotary speed, adjustable, steady start and stopTurntable sizeDia:1650mm Height:78mmTurntable weight capacity2000kgsFilm carriage systemPre-stretch film carriage, pre-stretch up to 250%,automatic transport filmUp and down uprightDouble chain structure, adjustable up and down speed by transducerControl systemPLC programmableMachine weight700kgMachi

Contact Now

ItemSpecificationArm performancePrecise sensitivity emergency brake system; Automatic arm reset.Film carriage systemPre-stretch film carriage, stretch ratio up to 250% or 300%, automatic film feeding & cutting device, adjustable speed.Lifting columnChain structure, speed variable frequency adjustable.Control systemPLC programmable control; Wrapping layer adjustable;Automatic height sense.The design ideas and concepts of the equipment system and management system are advanced.

Contact Now

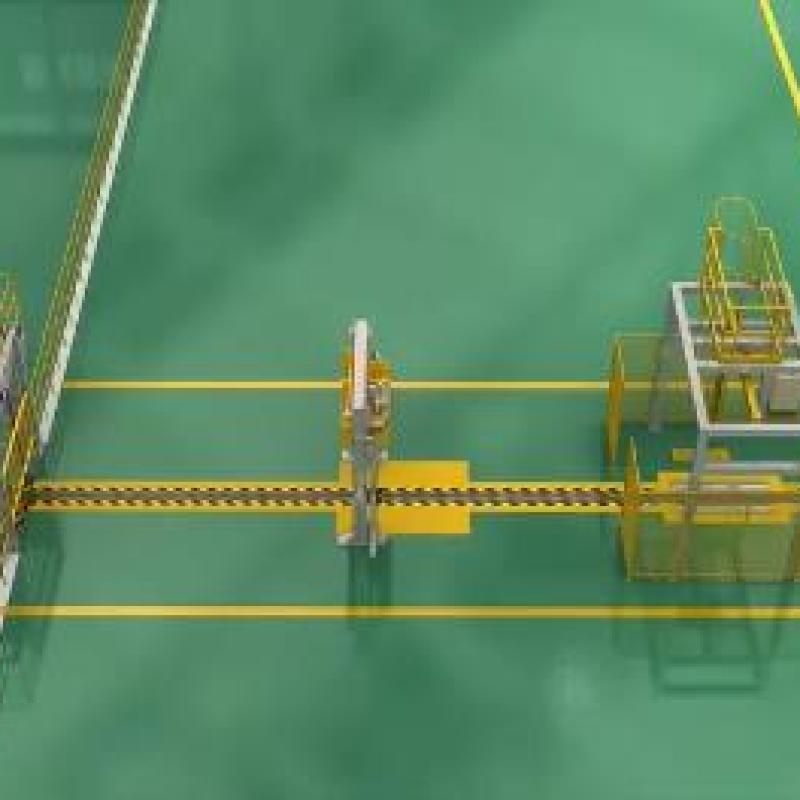

ItemSpecificationwrapping size(mm)500-1300mm (L)×500-1200(W)Wrapping height (mm)2200mmPacking efficiency20-40 loads / hourTurntable turning speed0-15rpm (Adjustable, soft start&stop)Roller conveying speed:18mpm adjustableTurntable diameter2000mmHeight of turntableTo be designed based on customer requirementsPower supply2.0KW 380V 50HZ 3PhaseMax. load capacity3000kgsAll equipment has high maintainability. There should be enough space for operation where the parts such as the motor and gearbox may be disassembled. Moving washer and protective cover.

Contact Now

Control systemPLC control systemPhoto eye pallet height sensor3-12 RPM variable turntable speed by frequency changerTurntableGo home position after wrap cycle finishedSoft start/soft stopHeavy duty chain driveFilm carriagePowered pre-stretch system to 300% to min film consumptionFilm delivery barlable speed by spparate AC Drive MotorHeavy duty double-chain carriage lift, calm and safetyOptionRampTop plate The system has the function of self-diagnosis and alarm, When the equipment in the conveying system breaks down in the process of operation, the system will send out sound and light alar

Contact Now

Technical specifications:Machine size:L5530×W2645×H3900 (mm)(max)Work efficiency:30 loads/H (wrapping and top-sheeting)Rotary speed: 15rpm Power supply:380Vac/3phases/50Hz, Air supply:0.5-0.6Mpa,Rotary arm stop by safety bumper and reflection photo eye sensing and obstacle in the rotating area.Powered pre-stretch system up to 250% to min film consumptionLifting unit in wrapping field will lift pallet up to 150mm above the roller conveyorFull auto feeding film and cutting film

Contact Now

Function of rotary arm:automatic brake system, automatic resetFilm carriage:pre-stretch film carriagethe stretch ratio up to 250%automatic stretch film feedingFilm lifting guide rail: double chain structure, the lifting speed adjustableControl system: PLC control system, wrapping layers and times adjustableAutomatic height detection of the goodsAuto film feeding: pneumatic driving, auto film feeding, auto film cuttingPower supply:AC 380V/ 50HZSeparate safety circuit with Pilz CE certi

Contact Now

Wrapping speed:30-60pallets/hRotating speed of the rotary arm:0-35rpm, variable frequency control motor drivingFunction of rotary arm:automatic brake system, automatic resetFilm carriage:pre-stretch film carriagethe stretch ratio up to 250%automatic stretch film feedingFilm lifting guide rail: double chain structure, the lifting speed adjustableControl system: PLC control system, wrapping layers and times adjustableAutomatic height detection of the goodsAuto film feeding: pneumatic dr

Contact Now

Wrapping speed:30-60pallets/hRotating speed of the rotary arm:0-35rpm, variable frequency control motor drivingFunction of rotary arm:automatic brake system, automatic resetFilm carriage:pre-stretch film carriagethe stretch ratio up to 250%automatic stretch film feedingFilm lifting guide rail: double chain structure, the lifting speed adjustableControl system: PLC control system, wrapping layers and times adjustableAutomatic height detection of the goodsAuto film feeding: pneumatic dr

Contact Now

Wrapping size: L(500-1300)mm*W(500-1200)mmWrapping height:H(1800-2600)mmWrapping speed:30-60pallets/hRotating speed of the rotary arm:0-35rpm, variable frequency control motor drivingFunction of rotary arm:automatic brake system, automatic resetFilm carriage:pre-stretch film carriagethe stretch ratio up to 250%automatic stretch film feedingFilm lifting guide rail: double chain structure, the lifting speed adjustableControl system: PLC control system, wrapping layers and times adjustableAutomatic height detection of the goodsAuto film feeding: &

Contact Now

Rotating speed of the rotary arm:0-35rpm, variable frequency control motor drivingFunction of rotary arm:automatic brake system, automatic resetFilm carriage:pre-stretch film carriagethe stretch ratio up to 250%automatic stretch film feedingFilm lifting guide rail: double chain structure, the lifting speed adjustableControl system: PLC control system, wrapping layers and times adjustableAutomatic height detection of the goodsAuto film feeding: pneumatic driving, auto film feeding, aut

Contact Now

Wrapping size: L(500-1300)mm*W(500-1200)mmWrapping height:H(1800-2600)mmWrapping speed:30-60pallets/hRotating speed of the rotary arm:0-35rpm, variable frequency control motor drivingFunction of rotary arm:automatic brake system, automatic resetFilm carriage:pre-stretch film carriagethe stretch ratio up to 250%automatic stretch film feedingFilm lifting guide rail: double chain structure, the lifting speed adjustableControl system: PLC control system, wrapping layers and times adjustableAutomatic height detection of the goodsAuto film feeding: &

Contact Now

Wrapping size: L(500-1300)mm*W(500-1200)mmWrapping height:H(1800-2600)mmWrapping speed:30-60pallets/hRotating speed of the rotary arm:0-35rpm, variable frequency control motor drivingFunction of rotary arm:automatic brake system, automatic resetFilm carriage:pre-stretch film carriagethe stretch ratio up to 250%automatic stretch film feedingFilm lifting guide rail: double chain structure, the lifting speed adjustableControl system: PLC control system, wrapping layers and times adjustableAutomatic height detection of the goodsAuto film feeding: &

Contact Now

Wrapping size: L(500-1300)mm*W(500-1200)mmWrapping height:H(1800-2600)mmWrapping speed:30-60pallets/hRotating speed of the rotary arm:0-35rpm, variable frequency control motor drivingFunction of rotary arm:automatic brake system, automatic resetFilm carriage:pre-stretch film carriagethe stretch ratio up to 250%automatic stretch film feedingFilm lifting guide rail: double chain structure, the lifting speed adjustableControl system: PLC control system, wrapping layers and times adjustableAutomatic height detection of the goodsAuto film feeding: &

Contact Now

Package length≤2200mmPackage diameter400mmCross section of goods(W×H)550X550mmPackaging speed4-6m/minPackaging efficiency40-60s/pieceOperation voltage380V.50HzMain engine power3.5KWPackaging material materialStretch film, anti rust composite paper, woven tape, aluminum plastic film, etcPacking material inner diameterΦ38,Φ50,Φ75Outer diameter of packaging materialsΦ150-Φ600Packaging material width50-120mmSwivel travelThe lifting stroke is 250mm; Horizontal movement 400mmAutomatic winding mechanism /ZSPneumatic controlPneumatic roof pressure /CSOptionalPneumatic roller protector /HGOptionalConve

Contact Now

Material: stretch filmWidth: 500mmThickness: 17-35μmInner Core: 76.2mmOuter-Dia.: ≤260 mmOpen-door type pre-stretch film carriage, stretch ratio 250% (1m to 3.5m)Film carriage lifting driving: chain driving, good stability and high reliability Driving reducer: worm gear reducer; Motor power: 0.75kw, SEW

Contact Now

1. Wrapping size500-1200mm (L) *500-1200mm (W)2. Packaging heightMax.2400mm (1800/2800mm availiable)3. Work efficiency20-40 loads/H4. Turntable speed0-12RPM (adjustable, soft start & stop)5. BearingMax. 2000kgs6. Turntable sizeD=1650mm, H=76mm7. Film carriagemotorised pre-stretch8. TowerDouble chain design. Lifting speed adjustable 9. Control systemPLC10. Weight600kgs11.

Contact Now

1. Wrapping size500-1200mm (L) *500-1200mm (W)2. Packaging heightMax.2400mm (1800/2800mm availiable)3. Work efficiency20-40 loads/H4. Turntable speed0-15RPM (adjustable, soft start & stop)5. BearingMax. 2000kgs6. Turntable sizeD=1650mm, H=78mm7. Film carriageDriven pre-stretch carriage,stretch ratio up to 300%8. TowerDouble chain design. Lifting speed adjustable 9. Control systemPLC10. Weight600kgs11. Dimension2745mm*1650mm*2860mm12.

Contact Now

1. Wrapping size500-1200mm (L) *500-1200mm (W)2. Packaging heightMax.2400mm (1800/2800mm availiable)3. Work efficiency20-40 loads/H4. Turntable speed0-12RPM (adjustable, soft start & stop)5. BearingMax. 2000kgs6. Turntable sizeD=1650mm, H=76mm7. Film carriagemotorised pre-stretch8. TowerDouble chain design. Lifting speed adjustable 9. Control systemPLC10. Weight600kgs11.

Contact Now

ItemSpecificationWork efficiency20-40 loads/HTurntable speed0-12RPM (adjustable, soft start & stop)BearingMax. 2000kgsFilm carriageDriven pre-stretch carriage, move up and down on side of the towerStretch ratioUp to 250%TowerDouble chain design. Lifting speed adjustableControl systemPLCRemarks: Some parts of the machine can be exchanged according to customer requirements.Option I: Standard low profile ramp.Option II: Weight scaleSeparate start, reset and emergency stop buttons.Manual carriage up/down switch .Turntable jog button.

Contact Now

ItemSpecificationFilm carriageDriven pre-stretch carriage, move up and down on side of the towerTowerDouble chain design. Lifting speed adjustableControl systemPLCRemarks: Some parts of the machine can be exchanged according to customer requirements.Option I: Standard low profile ramp.Option II: Weight scaleKickerKick out the rolls to the required position or equipments.

Contact Now

Feeding speed of the belt: 4.6m/sTension force, infinite regulation: 200-2500NHot melting sealing, length of sealing head: 27mmMaterial of belt: PET/PPWidth of belt: 9.5mm, 12.5mm,15.5mm Thickness of belt: 0.6-0.8mm The whole machine is equipped with automatic swords threading system.With the function of auto tape threading.The lifting of strapping heading is driven by gear motor SEW to ensure stable operation and reliable braking.With the strapping head of model VK10 K120-16 of TITAN Germany.

Contact Now