Max load size(mm)1200 (L)×1200(W) ×2000(H)mmPacking efficiency0-60 loads / hourRotary arm speed0-25rpmPower supply4.0KW 380V 50HZ 3PhaseMax load capacity2000kgsWrapping requirementBottom wrapping up to 2/3 of pallet, top wrapping 15cm higher than the height of palletWorking ambianceIndoor, normal temperatureUsed for the maintainer to climb to the top to do the maintenance.The safety guard fence can effectively protect the personal safety. The maintainer can stand on the maintenance platform to execute their work.

Contact Now

Palletizing speed400-1200 bags/hourLayers 1-10 layersAir supply 0.5-0.8 MpaPower supply380V/220V 50HZ+_10%Weight capacity(including mould)180-250kgRobtic palletizing and wrapping systems integrates palletzing, strapping, conveying and wrapping into automatic packing line with robot technology. It is widely applied in the industry of chemical , beverage,beer and other industries.It features with energy saving and high efficiency.

Contact Now

Max load size1200 L 1300W 2200H mmPacking efficiency 20-40 loads / hourArm speed 3-15rpmMachine weight 680kgPower supply 1.3KW 220V 50Hz 1Phase (standard)Material LLDPE Stretch FilmCore Diameter 76.2 mmFilm Width500 mmThe rotating parts of all driving parts are provided with protective cover. Automatic control system with emergency stop button to ensure safe production.

Contact Now

Capacity of tissue machine8rolls/HWorking time:24Hours /7 daysPaper roll diameter:φ1000-3500mmPaper roll width:±3700mmMax. Width including spool shaft:±5800mmTravel distance:±2*200m straight + 2*15m cross directionSimple and reliable design, stable workingAutomatic feeding, welding, cutting strap, make a flat and beautiful weldSide Motor drive moves on the two parallel rails, which keeps right strap position.One automatic wear sword slot can cross the center of turntable.

Contact Now

Feeding speed of the belt: 4.6m/sTension force, infinite regulation: 200-2500NHot melting sealing, length of sealing head: 27mmMaterial of belt: PET/PPWidth of belt: 9.5mm, 12.5mm,15.5mm Thickness of belt: 0.6-0.8mm The whole machine is equipped with automatic swords threading system.With the function of auto tape threading.The lifting of strapping heading is driven by gear motor SEW to ensure stable operation and reliable braking.With the strapping head of model VK10 K120-16 of TITAN Germany.

Contact Now

ItemSpecificationFilm carriageDriven pre-stretch carriage, move up and down on side of the towerTowerDouble chain design. Lifting speed adjustableControl systemPLCRemarks: Some parts of the machine can be exchanged according to customer requirements.Option I: Standard low profile ramp.Option II: Weight scaleKickerKick out the rolls to the required position or equipments.

Contact Now

Rotating speed of the rotary arm:0-35rpm, variable frequency control motor drivingFunction of rotary arm:automatic brake system, automatic resetFilm carriage:pre-stretch film carriagethe stretch ratio up to 250%automatic stretch film feedingFilm lifting guide rail: double chain structure, the lifting speed adjustableControl system: PLC control system, wrapping layers and times adjustableAutomatic height detection of the goodsAuto film feeding: pneumatic driving, auto film feeding, aut

Contact Now

Max load size(mm)1200 (L)×1200(W) ×2000(H)mmPacking efficiency0-60 loads / hourRotary arm speed0-25rpmPower supply4.0KW 380V 50HZ 3PhaseMax load capacity2000kgsWrapping requirementBottom wrapping up to 2/3 of pallet, top wrapping 15cm higher than the height of palletWorking ambianceIndoor, normal temperatureSimple and reliable design, stable workingAutomatic feeding, welding, cutting strap, make a flat and beautiful weldSide Motor drive moves on the two parallel rails, which keeps right strap position.One automatic wear sword slot can cross the center of turntable.

Contact Now

Function of rotary arm:automatic brake system, automatic resetFilm carriage:pre-stretch film carriagethe stretch ratio up to 250%automatic stretch film feedingFilm lifting guide rail: double chain structure, the lifting speed adjustableControl system: PLC control system, wrapping layers and times adjustableAutomatic height detection of the goodsAuto film feeding: pneumatic driving, auto film feeding, auto film cuttingPower supply:AC 380V/ 50HZSeparate safety circuit with Pilz CE certi

Contact Now

ItemSpecificationWrapping specifications(500-1300)mm*(500-1200)mm.Packing height2400mmPackaging efficiency30-60 loads/H available. (Option: or 20-40 loads/H)Arm speed0-25rpm frequency control.

Contact Now

Max load size(mm)1200 (L)×1200(W) ×2000(H)mmPacking efficiency0-60 loads / hourRotary arm speed0-25rpmPower supply4.0KW 380V 50HZ 3PhaseMax load capacity2000kgsWrapping requirementBottom wrapping up to 2/3 of pallet, top wrapping 15cm higher than the height of palletWorking ambianceIndoor, normal temperatureTurningarm speed: 3-15 rpmPallet dimensions: 800 X 1200 and 1000 X 1200Pallet height: Maximum 2200mm.

Contact Now

Material: stretch filmWidth: 500mmThickness: 17-35μmInner Core: 76.2mmOuter-Dia.: ≤260 mm Specification2.1 Strapping specification:Size of pallet: 1300mmx1300mmx2000mm2.2 Requirement for the placing of the pal

Contact Now

Wrapping speed:30-60pallets/hRotating speed of the rotary arm:0-35rpm, variable frequency control motor drivingFunction of rotary arm:automatic brake system, automatic resetFilm carriage:pre-stretch film carriagethe stretch ratio up to 250%automatic stretch film feedingFilm lifting guide rail: double chain structure, the lifting speed adjustableControl system: PLC control system, wrapping layers and times adjustableAutomatic height detection of the goodsAuto film feeding: pneumatic dr

Contact Now

Max load size(mm) 1200 (L)×1300(W) ×2200(H).Packing efficiency 20-40 loads / hour.Arm speed 3-15rpm.Power supply 1.3KW 220V 50HZ 1Phase.Photo-eye pallet height sensor. 0-9 separate top ,bottom & up-down wrap count selectors Photoeye sensing delay .Reinforce wrap allow more wrap on same location.Film Tension Control adjustment on the panel.315RPM arm variable a speed by frequency changerSeparate variable carriage up/down speed Cycle pause capability.Separate start, reset and emergency stop

Contact Now

Max load size(mm)1200 (L)×1200(W) ×2000(H)mmPacking efficiency0-60 loads / hourRotary arm speed0-25rpmPower supply4.0KW 380V 50HZ 3PhaseMax load capacity2000kgsWrapping requirementBottom wrapping up to 2/3 of pallet, top wrapping 15cm higher than the height of palletWorking ambianceIndoor, normal temperatureWhen stretch wrapping finish, the film will be cut and clamped automatically.When the film tail is released from the clamp, the air shooter will blow the film tail up, then the film tail will be wrapped by stretch film and keep it tightly with the pallet to ensure no film tail produce

Contact Now

ItemSpecificationWrapping specifications(500-1300)mm*(500-1200)mm.Packing height2400mmPackaging efficiency30-60 loads/H available.

Contact Now

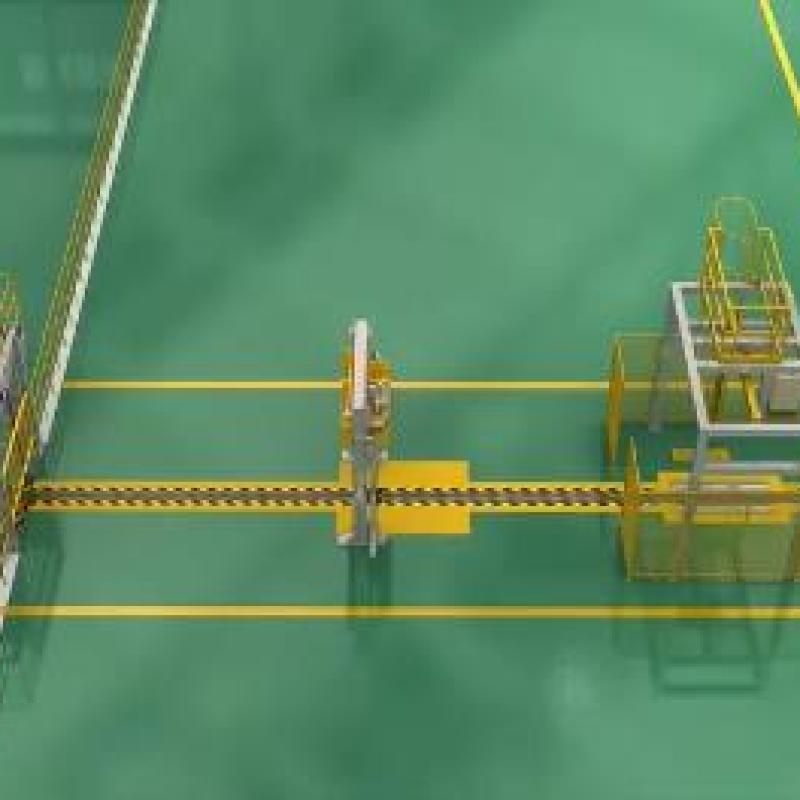

Voltage220/380V 50/60HZ 3PWrapping Size(L*W mm)(500-1100)*(500-1200)Wrapping Height500-1800/2400Capacity20-40 Pallet/HourTurntable size2000mmTurntable Height400mmIntelligent Conveying and Packaging System Paper Roll Conveying and Packaging System in Papermaking Completion Section. Paper roll conveying and packaging system is mainly used for paper roll conveying and packaging in paper mills. Use special machinery and advanced control system to complete automatic and manual conveying, stopping, turning, weighing, code spraying, labeling, turning and packaging of paper rolls.

Contact Now

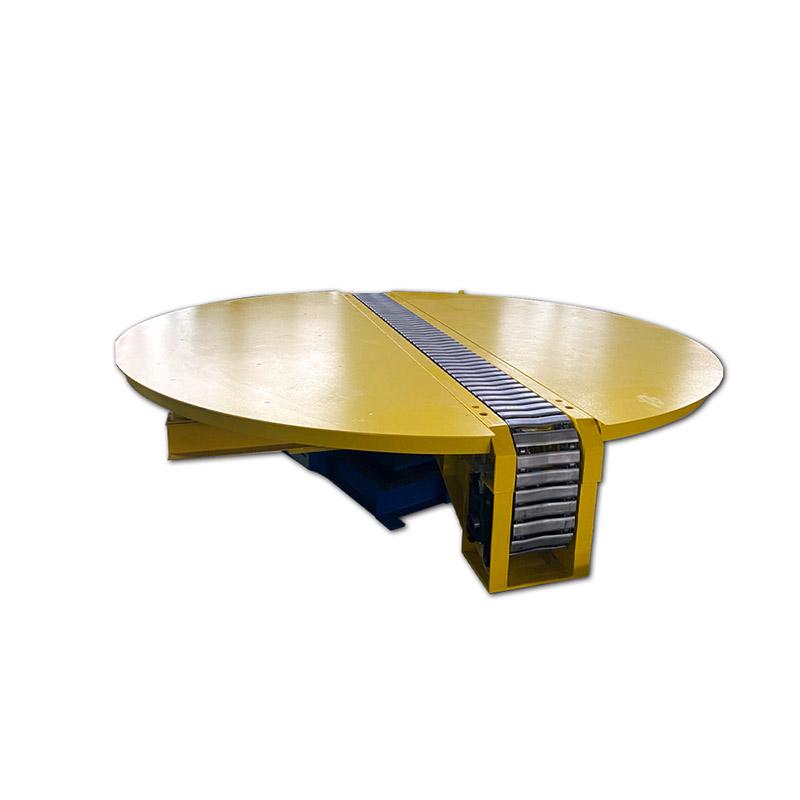

ItemSpecificationwrapping size(mm)500-1300mm (L)×500-1200(W)Wrapping height (mm)2200mmPacking efficiency20-40 loads / hourTurntable turning speed0-15rpm (Adjustable, soft start&stop)Roller conveying speed:18mpm adjustableTurntable diameter2000mmHeight of turntableTo be designed based on customer requirementsPower supply2.0KW 380V 50HZ 3PhaseMax.

Contact Now

Wrapping specifications(400~1200mm) x (180~400mm) x (300~600mm)Rotating speed20RPM (turntable transducer adjust, steady stop and start)Film carriage systempre-stretch film carriageMachine weight200kgMachine dimension1595mm×600mm×1194mmStrong steel frame to keep film carriage running steady during wrapping progress.Height: to be designed according to the packing height 2,000-2800mm.

Contact Now

Max load size(mm)1200 (L)×1200(W) ×2000(H)mmPacking efficiency0-60 loads / hourRotary arm speed0-25rpmPower supply4.0KW 380V 50HZ 3PhaseMax load capacity2000kgsWrapping requirementBottom wrapping up to 2/3 of pallet, top wrapping 15cm higher than the height of palletWorking ambianceIndoor, normal temperatureStop the finishing rolls coming from the rewinder and releaserolls to the V-type slat conveyor according in order.Change the gap conveying into the continuos conveying.

Contact Now

Wrapping speed:30-60pallets/hRotating speed of the rotary arm:0-35rpm, variable frequency control motor drivingFunction of rotary arm:automatic brake system, automatic resetFilm carriage:pre-stretch film carriagethe stretch ratio up to 250%automatic stretch film feedingFilm lifting guide rail: double chain structure, the lifting speed adjustableControl system: PLC control system, wrapping layers and times adjustableAutomatic height detection of the goodsAuto film feeding: pneumatic dr

Contact Now

Rotating ring inner diameter1200-2000mmWrapping dimensionWidth: 500-1100mm; Height: 500-1000mm; Length: 500-2000mmRotating ring speedMax.

Contact Now

Wrapping size: L(500-1300)mm*W(500-1200)mmWrapping height:H(1800-2600)mmWrapping speed:30-60pallets/hRotating speed of the rotary arm:0-35rpm, variable frequency control motor drivingFunction of rotary arm:automatic brake system, automatic resetFilm carriage:pre-stretch film carriagethe stretch ratio up to 250%automatic stretch film feedingFilm lifting guide rail: double chain structure, the lifting speed adjustableControl system: PLC control system, wrapping layers and times adjustableAutomatic height detection of the goodsAuto film feeding: &

Contact Now