ItemSpecificationWrapping specifications(500-1300)mm*(500-1200)mm.Packing height2400mmPackaging efficiency30-60 loads/H available.

Contact Now

Chain pitchP = 63.5 mmSlat widthB = 55 mmSlat lengthL = 250 mmThicknessS = 8 mm Stainless steel 304Turntable diameterDesign based on paper reel sizeAfter finishing stretch wrapping, the film tail will be cut and next film head is clamped automatically. Air blowing to wrap film head into pallet.Hot cutting wire to cut the film after wrapping, and then wiper arm brush against film tail.

Contact Now

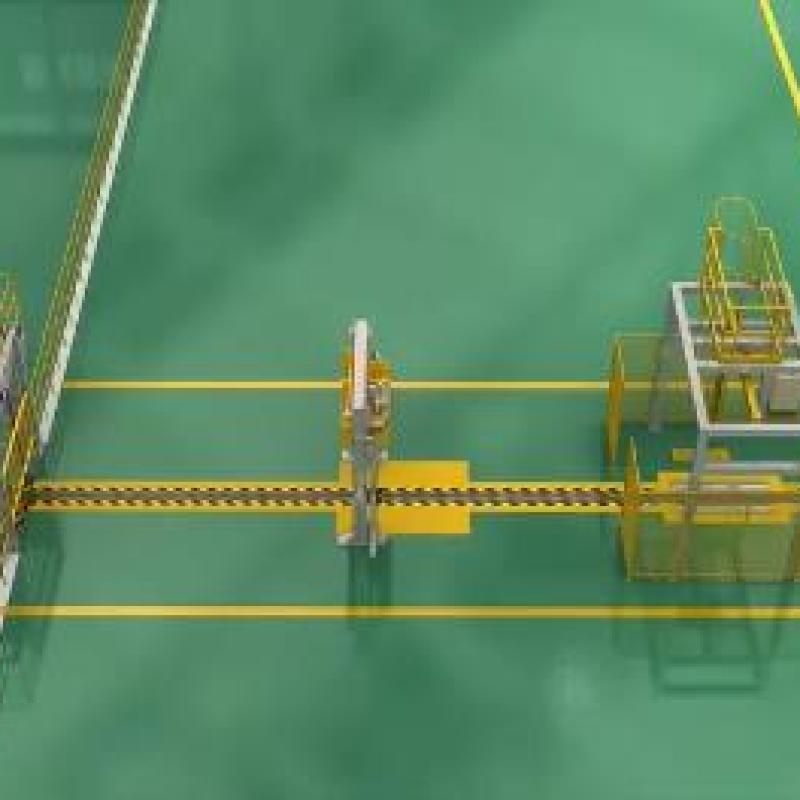

Voltage220/380V 50/60HZ 3PWrapping Size(L*W mm)(500-1100)*(500-1200)Wrapping Height500-1800/2400Capacity20-40 Pallet/HourTurntable size2000mmTurntable Height400mmIntelligent Conveying and Packaging System Paper Roll Conveying and Packaging System in Papermaking Completion Section. Paper roll conveying and packaging system is mainly used for paper roll conveying and packaging in paper mills. Use special machinery and advanced control system to complete automatic and manual conveying, stopping, turning, weighing, code spraying, labeling, turning and packaging of paper rolls.

Contact Now

Gram weight:100g/m2Moisture:7%Mechanical performance:Suitable for non-tear rolled edgeWrapping crimping distance:100mmFolding side width:100mm every sideMain material of the frame: Q235-AThe surface of the 7 paper guide rollers is galvanized with a diameter of Ф100mm.4 sets of tension controller, using motor frequency control.4 sets of paper holder pneumatic clamping mechanism, including 8 cylinders.4 pneumatic control boxes and pneumatic control components used.Compressed air lines, fittings and accessories used inside the packaging machine.The gas point is connected to the gas point by the b

Contact Now

Wrapping speed:30-60pallets/hRotating speed of the rotary arm:0-35rpm, variable frequency control motor drivingFunction of rotary arm:automatic brake system, automatic resetFilm carriage:pre-stretch film carriagethe stretch ratio up to 250%automatic stretch film feedingFilm lifting guide rail: double chain structure, the lifting speed adjustableControl system: PLC control system, wrapping layers and times adjustableAutomatic height detection of the goodsAuto film feeding: pneumatic dr

Contact Now

ItemSpecificationArm performancePrecise sensitivity emergency brake system; Automatic arm reset.Film carriage systemPre-stretch film carriage, stretch ratio up to 250% or 300%, automatic film feeding & cutting device, adjustable speed.Lifting columnChain structure, speed variable frequency adjustable.Control systemPLC programmable control; Wrapping layer adjustable;Automatic height sense.The design ideas and concepts of the equipment system and management system are advanced.

Contact Now

Function of rotary arm:automatic brake system, automatic resetFilm carriage:pre-stretch film carriagethe stretch ratio up to 250%automatic stretch film feedingFilm lifting guide rail: double chain structure, the lifting speed adjustableControl system: PLC control system, wrapping layers and times adjustableAutomatic height detection of the goodsAuto film feeding: pneumatic driving, auto film feeding, auto film cuttingPower supply:AC 380V/ 50HZSeparate safety circuit with Pilz CE certi

Contact Now

Rotating speed of the rotary arm:0-35rpm, variable frequency control motor drivingFunction of rotary arm:automatic brake system, automatic resetFilm carriage:pre-stretch film carriagethe stretch ratio up to 250%automatic stretch film feedingFilm lifting guide rail: double chain structure, the lifting speed adjustableControl system: PLC control system, wrapping layers and times adjustableAutomatic height detection of the goodsAuto film feeding: pneumatic driving, auto film feeding, aut

Contact Now

ItemSpecificationMax. load size (LxWxH)(500-1300)mm×(500-1200)mm×(1800-2400)mm.Packing efficiency20-40 loads / hourRotary arm speed0-15 rpm Frequency controlPower supplyAC 220VMax load capacityFloor capacityWorking ambienceIndoor, normal temperatureMachine dimensionsSubject to final designSlewing bearing drive system;Soft start/soft stopWhen wrapping process finished as set, the arm auto back to home position.

Contact Now

No.ItemBrandOrigin1PLC & touch screenSiemensGermany2InverterSchneiderFrance3Proximity switchOmronJapan4Limit switchOmronJapan5Power switchSchneiderFrance6RelayOmronJapan7PhotoeyePanasonicJapan8Pneumatic partsAirtecRodless cylinder: SMCTaiwan, ChinaJapan9MotorChinese brandChinaThe cease sorting deck is composed through the 12 unit.

Contact Now

Capacity of tissue machine8rolls/HBearing capacity:Max. 10tons (including spool shaft)Working time:24Hours /7 daysPaper roll diameter:φ1000-3500mmPaper roll width:±3700mmMax. Width including spool shaft:±5800mmTravel distance:±2*200m straight + 2*15m cross directionTravel speed:Max. 40m/min (loaded)Max. 60m/min (unloaded)Paper roll conveyor system--V-type slat conveyor1. The V type is especially made for the paper roll.2. The v-slat conveyor is usually used in the paper roll packing and transporting system.3.

Contact Now

Max load size(mm)1200 (L)×1200(W) ×2000(H)mmPacking efficiency0-60 loads / hourRotary arm speed0-25rpmPower supply4.0KW 380V 50HZ 3PhaseMax load capacity2000kgsWrapping requirementBottom wrapping up to 2/3 of pallet, top wrapping 15cm higher than the height of palletWorking ambianceIndoor, normal temperatureTurningarm speed: 3-15 rpmPallet dimensions: 800 X 1200 and 1000 X 1200Pallet height: Maximum 2200mm.

Contact Now

No.ItemBrandOrigin1PLC & touch screenSiemensGermany2InverterSchneiderFrance3Proximity switchOmronJapan4Limit switchOmronJapan5Power switchSchneiderFrance6RelayOmronJapan7PhotoeyePanasonicJapan8Pneumatic partsAirtecRodless cylinder: SMCTaiwan, ChinaJapan9MotorChinese brandChinaPallet dimension: L1200mm * W1200mm * H1800mmVolt: 380Volts, 50Hz, 3 phaseTop sheet length: adjustable according to the pallet (normally 1200mm+2*300mm)Sheet delivery speed: 9.5m/minFilm feeding frame moving speed: 4.5m/min

Contact Now

Max load size(mm)1200 (L)×1200(W) ×2000(H)mmPacking efficiency0-60 loads / hourRotary arm speed0-25rpmPower supply4.0KW 380V 50HZ 3PhaseMax load capacity2000kgsWrapping requirementBottom wrapping up to 2/3 of pallet, top wrapping 15cm higher than the height of palletWorking ambianceIndoor, normal temperatureWhen stretch wrapping finish, the film will be cut and clamped automatically.When the film tail is released from the clamp, the air shooter will blow the film tail up, then the film tail will be wrapped by stretch film and keep it tightly with the pallet to ensure no film tail produce

Contact Now

Technical specifications:Machine size:L5530×W2645×H3900 (mm)(max)Work efficiency:30 loads/H (wrapping and top-sheeting)Rotary speed: 15rpm Power supply:380Vac/3phases/50Hz, Air supply:0.5-0.6Mpa,Rotary arm stop by safety bumper and reflection photo eye sensing and obstacle in the rotating area.Powered pre-stretch system up to 250% to min film consumptionLifting unit in wrapping field will lift pallet up to 150mm above the roller conveyorFull auto feeding film and cutting film

Contact Now

ItemSpecificationWrapping specifications(500-1300)mm*(500-1200)mm.Packing height2400mmPackaging efficiency30-60 loads/H available.

Contact Now

Capacity of tissue machine8rolls/HBearing capacity:Max. 10tons (including spool shaft)Working time:24Hours /7 daysPaper roll diameter:φ1000-3500mmPaper roll width:±3700mmMax. Width including spool shaft:±5800mmTravel distance:±2*200m straight + 2*15m cross directionTravel speed:Max. 40m/min (loaded)Max.

Contact Now

ModelXL-01Wrapping specifications(400~1200mm) x (180~400mm) x (300~600mm)Rotating speed20RPM (turntable transducer adjust, steady stop and start)Max. load100kgFilm carriage systempre-stretch film carriageMachine weight200kgMachine dimension1595mm×600mm×1194mm Semi-automatic model; PLC easy operation control; Pre-stretch system up to 300% of the film length (customized); Auto cut & grab film after wrap finished.Stable performance, working life 10 years, quality guarantee 1 year.

Contact Now

Technical Parameter:ModelT1650FMax.wrapping height 2.4mUpright height2.8mTurntable loading2000kgTurntable speed0-15bpm/minFilm frame up&down speed0-90mm/sSupply110V-220V/50-60Hz 1PhasePacking efficiency20-40packs/hourGross weight700kgMachine sizeL2545*W1650*H2880mmPackage sizeL2740*W1760*H980mm Feature:1.Heavy load capacity2.Variable turntable speed and film carriage up down speed3.Manual/auto exchange4.PLC control,wrapping cycle can setting,more economic5.Pre stretch film carriage,more save stretch

Contact Now

Chain pitchP = 63.5 mmSlat widthB = 55 mmSlat lengthL = 250 mmThicknessS = 8 mm Stainless steel 304Turntable diameterDesign based on paper reel sizeThe photoelectric switch is installed on the film carriage, automatic detect the height of the pallet

Contact Now

Chain pitch: P = 63.5 mm Slat width: B = 55 mm Slat length: L = 250 mm Thickness: S = 8mm, 16 Mn Steel Conveyor height 12000mm*5 sets+17500mm*1 set Conveyor height 800mm Speed of conveyors 18m/min (Can be adjusted or as required) Slat bearing,Gear motor Chinese brand Power 3kW+4kW (or as required)chain conveyer, chain pitch P=63.5mm,V-slat width:B=50mm,slat length:B=250mm,Thickness:S=8 mm,Material 16 manganese.2. Slat are being made V type to transport paper rolls with a 170-degree angle.3.

Contact Now

Technical dataItemSpecificationWrapping specifications(500-1300)mm*(500-1200)mm.Packing height2400mmPackaging efficiency30-60 loads/H available.

Contact Now

Control systemPLC control systemPhoto eye pallet height sensor3-12 RPM variable turntable speed by frequency changerTurntableGo home position after wrap cycle finishedSoft start/soft stopHeavy duty chain driveFilm carriagePowered pre-stretch system to 300% to min film consumptionFilm delivery barlable speed by spparate AC Drive MotorHeavy duty double-chain carriage lift, calm and safetyTechnology DataMax load size(mm): 1200(L)X1200(W)X2400(H)Turntable dia: 1650mmTurntable Height: 77mmTurntable weight capacity: 2000kgsTurntable speed: 3-12rpmElectrics: 220V 50HZ 1 phasePower: 1.5KWConveyo

Contact Now

V-slat conveyorChain pitch:P = 63.5 mmSlat width:B = 55 mmSlat length:L = 250 mmThickness:S = 8mm, Stainless steel or Carbon steelLength of conveyorCustomizedNo. Of conveyorCustomizedSpeed of conveyors18m/min or customizedSlat bearing:HRB, ChinaGear motor:SEW, Germany or Chinese famous motorThe conveyor slat is made in V-Shaped, Angle: 170°. --Loading capacity of slat conveyor: 3000 kg/m .--Chain rollers installed with bearing inside, No oil and No contamination on paper rolls.--Heavy duty steel structures, modular design.

Contact Now